Investigations by researchers have shown that in Sharp-Crested Weirs even very slight rounding or dulling of the square upstream edge of the weir crest has a measureable effect on discharge.

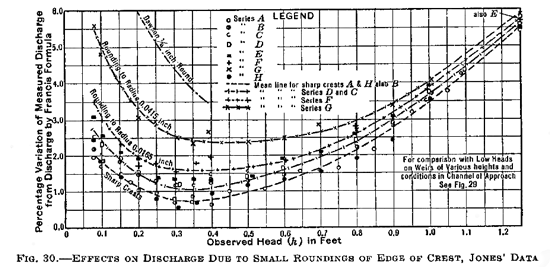

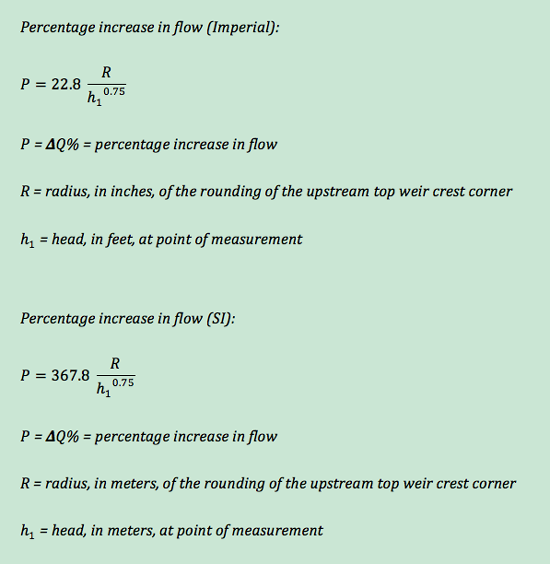

Jones found that for crest radii up to 1/8-inch [0.3175 cm] the rounding increases the discharge in direct proportion to the radius, and the percentage effect decreases as the head increases. This is to be expected as small variations in flow or installation conditions at low heads should naturally be expected to have a greater influence than at greater heads.

It is for this reason that the choice of weir plate material is so important and that wooden or plywood weirs are not recommended for any attempt at accurate flow measurement. Stainless steel (surface water applications) and fiberglass (industrial applications) are the preferred materials of construction. Both are strong and can be formed to precise tolerances.

In installations demanding extreme accuracy the crest must be kept square, with rounding kept to a minimum. When combined with surface roughness, the increase in discharge error due to weir crest rounding can be 1-2% - or doubling the standard 2% error of thin-plate weirs.

Image: Flickr

Sources: Schoder, E., Turner, K., Precise Weir Measurements, Transactions of the American Society of Civil Engineers, Vol. 93, No. 1, January, 1929, Jones, O., The Effect on Orifice and Weir Flow of Slight Roundings of the Upstream Edge, The Cornell Civil Engineer, 26, No. 2, November, 1917, No. 3, December, 1917