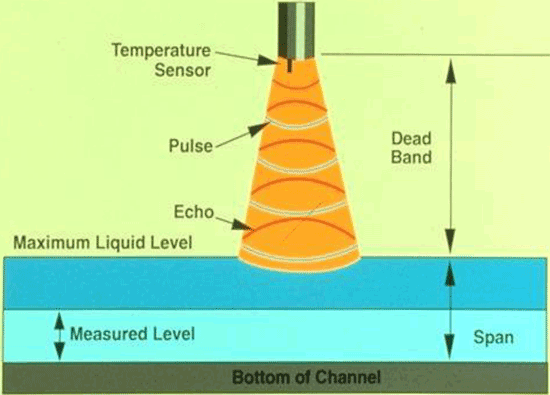

Ultrasonic flow meters measure the level in a channel by transmitting a pulse of sound from the face of the sensor to the surface of the flow stream and measuring the time for the echo to return. The transit time corresponds to the distance between the face of the sensor and the surface of the water.

Ultrasonic flow meters measure the level in a channel by transmitting a pulse of sound from the face of the sensor to the surface of the flow stream and measuring the time for the echo to return. The transit time corresponds to the distance between the face of the sensor and the surface of the water.

When the meter is initially set up, a pre-determined distance (or level in some meters) is set. This distance is either the zero level (no flow present) or a specific level in the flume or weir. With this initial calibration it is only a matter of simple arithmetic to determine the liquid level. This level is then applied to either pre-programmed discharge equations or strapping tables to output a flow rate.

Because the sensor is not in contact with the water, ultrasonic sensors have no scheduled maintenance. Ultrasonic sensors are not affected by chemicals, grease, suspended solids, or silt in the flow stream.

Performance of ultrasonic flow meters may be degraded by:

- Strong wind

- Solar heating (of the sensor)

- Foam

- Turbulence

- Steam

- False echoes from obstructions

To combat these problems a variety of methods are used:

- Sensor sunshades (for solar heating)

- Angling the sensor face (to reduce steam condensate build up)

- Proprietary control schemes are used to adjust amplifier gain (to increase echo strength)

- Variable blanking distances (to eliminate early / late echo returns)

- Dampening factors (applied to reduce peaks and troughs in the output signal).

For maximum performance, ultrasonic flow meters are not recommended for use on channels less than 6-inches [15.24 cm] wide (due to beam spread) or where steam, foam, turbulence, floating debris / oil / grease are present (although as seen above these conditions can sometimes be mitigated).

To obtain maximum accuracy a temperature sensor [either integral to the ultrasonic sensor (preferred) or as a stand alone sensor] is required to compensate for changes in air temperature.

Dead span (the distance measured from the face of the sensor in which sensor exhibits degraded performance) is typically 1-foot [0.3048 m], while the range for flow measurement sensors is typically up to 11-feet [3.353 m].

Under standard conditions (still air, 40-70% relative humidity, 72° F [22.22° C]), the level measurement accuracy of ultrasonic flow meters can ± 1/4 to 3/8-inch [0.635 to 0.9525 cm] (depending upon the change in level).

When mounting a ultrasonic sensor over a flume (or weir) there is a tradeoff between accessibility (mounting the sensor near the side of the flume) and maximum potential accuracy (mounting the sensor over the centerline of the flume). If the flow approaching the flume has been properly conditioned and the flume properly set, either condition is acceptable. If, however, the flow has not been properly conditioned, is turbulence, or is poorly distributed, readings at the sidewall may differ from those in the center of the flume. Don't assume, though, that the centerline reading is automatically more accurate.

Image: Teledyne-ISCO