In the almost 100 years since Dr. Parshall developed his flume, the Parshal Flume has been installed in several different ways and adapted to a number of different connection types.

Parshall Flume Mounting

Concrete Channels

Concrete encapsulation is the most common method of installing a Parshall Flume. The flume is set in an oversized, roughed in the channel, and then grouted into place. To help secure the flume during installation and make sure that it does not float out of place, wire is run through the anchor clips on the outside of the flume back to rebar before the grout pour begins.

Concrete encapsulation is the most common method of installing a Parshall Flume. The flume is set in an oversized, roughed in the channel, and then grouted into place. To help secure the flume during installation and make sure that it does not float out of place, wire is run through the anchor clips on the outside of the flume back to rebar before the grout pour begins.

In both concrete and earthen channel installations, the inside of the Parshall Flume must be cribbed and weighted so that the flume does not shift out of place or the sidewalls / floor distort. Once the installation is finished, the cribbing is removed.

Earthen Channels

Earthen channel installations are typical where Parshall Flume measure watersheds or water rights apportionment / irrigation flows. An oversized area is excavated, the flume is typically bedded on a compactable base, and then the area around the flume is backfilled. To help secure the flume in place, earth anchors or threaded rod are typically run through the anchor clips on the outside of the flume.

Earthen channel installations are typical where Parshall Flume measure watersheds or water rights apportionment / irrigation flows. An oversized area is excavated, the flume is typically bedded on a compactable base, and then the area around the flume is backfilled. To help secure the flume in place, earth anchors or threaded rod are typically run through the anchor clips on the outside of the flume.

Flow bypass can be a concern upstream of the flume and a watertight geotextile can be used to help stop it. Similarly, a geotextile can be used downstream - where scour can occur.

In both concrete and earthen channel installations, the inside of the Parshall Flume must be cribbed and weighted so that the flume does not shift out of place or the sidewalls / floor distort. Once the installation has been completed, the cribbing is removed.

Integrated Enclosures

Above grade industrial flows may require a way to secure access to a flume. For those applications, Openchannelflow offers factory integration of a 1 or 2-inch Parshall Flume into one of our Redstone Fiberglass Equipment Enclosures.

Above grade industrial flows may require a way to secure access to a flume. For those applications, Openchannelflow offers factory integration of a 1 or 2-inch Parshall Flume into one of our Redstone Fiberglass Equipment Enclosures.

The result is a secure, integrated solution that allows for the accurate measurement of flows while maintaining data integrity.

Flow Metering Manholes

For applications where below grade flow monitoring is required, Openchannelflow offers Parshall Flumes integrated into our fiberglass Packaged Metering Manholes.

Parshall Flume End Connections

End Adapter

The end connections for Parshall Flumes revolve around the end adapter. The end adapters are rectangular structures that attach to the end of the flume that allows flow to be transitioned into / out of the flume in a controlled manner.

The end connections for Parshall Flumes revolve around the end adapter. The end adapters are rectangular structures that attach to the end of the flume that allows flow to be transitioned into / out of the flume in a controlled manner.

End adapters can be provided with pipe stubs, flanges, or caulking collars to connect to piping. Additionally, open-ended end adapters are also available.

In addition to transitioning flow into / out of the flume, end adapters are also convenient locations to mount other accessories that otherwise would not fit in the flume itself.

Staged Manhole Transitions

Starting with the standard Parshall end adapter, a curved is molded at the inlet so the flume can connected to the manhole wall – eliminating the need to either form a transition or have a pipe connection to the flume.

Starting with the standard Parshall end adapter, a curved is molded at the inlet so the flume can connected to the manhole wall – eliminating the need to either form a transition or have a pipe connection to the flume.

Staged transitions are available for select sizes of Parshall Flumes and manhole diameters. Contact Openchannelflow for additional details.

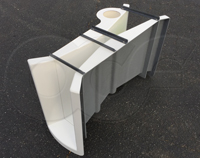

Wing Wall Transitions

Wing walls are radiused (or flat) plates attached to the flume to direct flow into or out of the flume from the larger channel installed in.

Wing walls are radiused (or flat) plates attached to the flume to direct flow into or out of the flume from the larger channel installed in.

Wing walls can be factory attached or shipped loosed for field installation as required.

Inlet Parshall flume wing walls should always be of the radius type. Research has shown that flat 45º inlet wing walls can adversely affect flow in the flume's converging section.

Customization

Flume Stand

For applications where the flume is to site above grade, Openchannelflow can provide stands to raise the flume. The stand can be molded into the flume, or a separate structure on which the flume is mounted.