Periodically we are asked the question: Can Parshall flumes be made out of concrete? The answer is: yes, they can (but they usually aren’t)!

The use of concrete in makiing Parshall flumes is limited by a number of factors:

- Ready availability of fiberglass and galvanized steel Parshall flumes

- Process Compatibility

- Dimensional tolerance required

- Equipment needs

- Limited design flexibility

Historical Use of Concrete

In his investigation of what would become the Parshall flume, Dr. Parshall used a variety of materials, including: sheet metal, wood, and concrete to from his flumes.

It is important to note that Dr. Parshall was involved with the install of a large number of sites (130) so he developed metal forms with which he constructed his concrete Parshall flumes. Metal forms are expensive and unless there are a large number of identical flumes, the cost associated with making the forms is prohibitive unless spread out over a number of units.

Flume Size and Material of Construction

For Parshall flumes from 1-inch to 120-inch in size, fiberglass is the predominant material of construction for most applications*. At the 144-inch size, flumes are formed either in fiberglass or concrete, with fiberglass still the norm. At 180-inches concrete is almost always used. Above 180-inches concrete is always used.

Part of the reason is this: Parshall flumes from 12-inches to 120-inches share the same throat, discharge, and sidewall geometry. A single adjustable mold can be made from which a wide range of Parshall flume sizes can be made. At 144-inches a new mold is required as these dimensions change - as they do again for the 180-inch size.

In given any year (or sometimes years) there are few applications across the industry requiring Parshall flumes 144-inches in size - not even enough to support each fiberglass flume manufacturer having a 144-inch Parshall flume mold (a mold which takes considerable time and money to fabricate). Applications requiring Parshall flumes 180-inches and larger are rarer still – with almost no fiberglass Parshall flume manufacturers having even temporary molds.

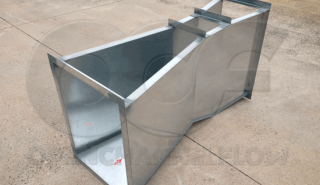

*Galvanized steel Parshall flumes have a strong presence in water rights / irrigation applications.

The Impact of Transportation

Transport of large fiberglass flumes is also an issue. The 144-inch Parshall flume, in fiberglass, ships in three pieces and takes one and a half flat bed trailers. Competition, therefore, tends to be very localized - with fabricators usually (but not always) owning their local markets.

Process Compatibility

In wastewater / sewage treatment plants Parshall flumes are almost exclusively made from fiberglass. The isophthalic polyester resins used in their construction are highly resistant to hydrogen sulfide.

Hydrogen sulfide attacks concrete with such efficiency that it is standard practice in many parts of the United States to coat concrete channels at treatment plant headworks to increase their longevity.

Dimensional Tolerances

JIS (B7553) and ASTM (D 1941-91(2001) call for Parshall flume dimensions to be +/- 1-2%. For a 3-inch Parshall this means that the throat width should deviate no more than 1/16th of an inch [0.1588 cm] - a level of accuracy extremely difficult to achieve with field formed concrete.

As Parshall flumes get larger, though, this level of accuracy becomes more attainable. At 144-inches (the point at which concrete is occasionally used), the ASTM throat tolerance is 2 7/8-inches [7.303 cm] - more than achievable in concrete construction.

Configuration Flexibility

With the metal forms required to make concrete flumes there is a lack of design flexibility. Modifications to accommodate different inlet geometry, custom sidewall heights, or molded-in accessories are essentially impossible with out a complete (and expensive) rebuild of the form for each specific application.

Fiberglass on the other hand is extremely adaptable. Molded-in sidewall cavities, inlet transitions, and more can be added either temporarily or permanently to fiberglass molds without much difficulty. Fiberglass also lends itself to the integration of flow conditioning structures, end adapters, and even integration into fiberglass manholes – to form monolithic, watertight, packaged flow metering manholes!

Images: Parshall, R., Improving the Distribution of Water to Farmers by Use of the Parshall Measuring Flume, Bulletin 488, Colorado Agricultural Experiment Station, Colorado A&M College, May, 1945, Ralph L. Parshall Collection - Colorado State University