Recently an industrial customer of Openchannelflow installed one of our fiberglass Packaged Metering Manholes and documented the steps involved in its installation.

The Packaged Metering Manhole is located next to the customer’s loading docks, so a traffic loaded (H-20) top style was chosen for the installation. To measure their effluent flows, the Packaged Metering Manhole integrates a 3-inch Parshall flume (primary device). Flow through the flume is then measured with a Teledyne ISCO Signature bubbler flow meter (secondary device) with an Electro-Chemical Devises pH probe / transmitter for parameter monitoring.

Excavate the site

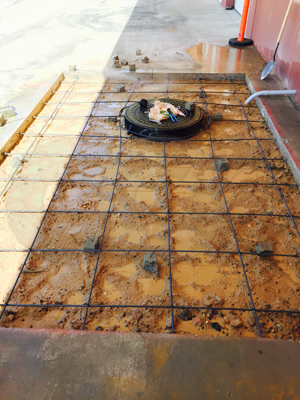

Forming the Concrete Pad

The concrete pad that the Packaged Metering Manhole mounts to should be smooth and level.

Setting the Manhole

As the slab was smooth and level, the contractor decided to omit the installation of the foam pad provided with each Packaged Metering Manhole. The manhole is secured through the use of stainless steel concrete wedge anchors.

Connecting the Manhole to the Process Line

Most Packaged Metering Manholes are provided with pipe stubs to connect to the process line. For these applciations it is common to use Fernco's 1056 lne of flexible couplings. High temperature / chemically agressive applciations may require the use of neopreme couplings or molded fiberglass flanges.

At this point, once the manhole has been connected to the monitored line, flow can resume - even before the rest of the installation has been completed. At a preapred site, the flow only needs to be diverted or blocked for a few minutes, resulting in minimal line down time.

Backfilling / Setting the H-20 Stack

This particular application required more than the usual amont of grade rings to bring the manhole up to grade. Operatational issues at the customer's plant meant that the contractor had to estimate the line depth based upon construciton documents from when the facility was first built. Based upon previous work the contractor had performed at the plant, they viewed the construciton documents with some skepticism and deliberately ordered the manhole shorter than otherwsie would have been called for. Typically a H-20 Packaged Metering Manhole is sized so that the shoulder of the manhole is a 12-inches [30.48 cm] below surface grade.

Finish to Grade

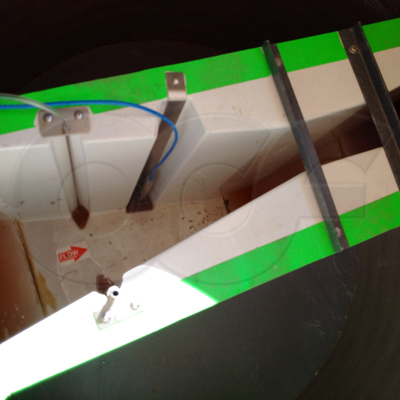

Installing the Flow Meter

Te

Te

The customer excavated the installation site Friday afternoon. The installation of the Packaged Metering Manhole took place Saturday morning, and the plant was up and running as usual on Monday. The result was that the customer experienced no plant down time and were able to meet their discharge reporting requirements to the City ahead of schedule!

Excavation and forming the concrete pad took the longest. To shorten instalaltion times, some customers use a pad poured off-site / pre-purchase a pad so that the manhole can be pre-mounted to it and the whole assembly dropped into place once the excavation has been completed!