This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Disadvantages of Palmer Bowlus Flumes

Since its introduction in the 1930’s, the Palmer Bowlus Flume has grown to be the second most common flume for measuring sanitary flows. There are, however, several distinct disadvantages in using Palmer Bowlus flumes.

Lack of Standardization

Unlike other styles of flumes that have strictly defined sizes, configurations, and flow characteristics, the Palmer Bowlus is a class of U-shaped flumes with a raised throat ramp.

While a standard (ASTM D5390 - 93(2013) Standard Test Method for Open-Channel Flow Measurement of Water with Palmer Bowlus Flumes) does exist, the standard only lays out the general shape of the flume - and not specifics as with ASTM D1941 for Parshall flumes.

The shape of the ramp can greatly affect the flumes capacity and flow sensitivity and is not standardized. As a result, each Palmer Bowlus flume is generally proprietary to each manufacturer and rating tables / equations for one manufacturer’s flume may not be valid for another’s.

Decreased Accuracy at Lower Flows

Under normal flow conditions where the head in a Palmer Bowlus is large in comparison to the throat length, a Palmer Bowlus flume is typically accurate to +/-3-5%.

But when the flows drop and the head is small in comparison to the throat length, the accuracy drops to +/-4-6%.

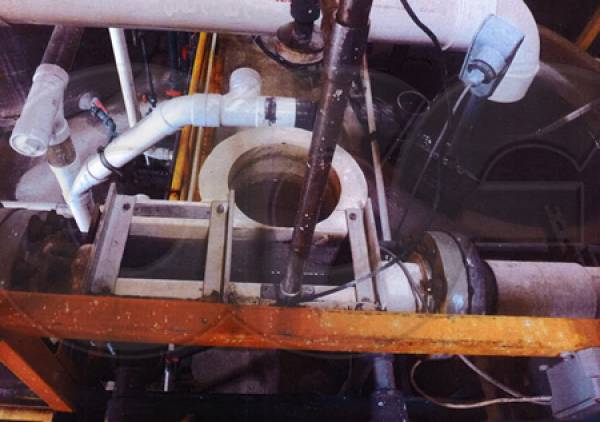

Upstream Sedimentation

Because the Palmer Bowlus flume has a raised throat ramp, upstream sedimentation can be a problem. This is particularly true when the solids are dense / the flows are low.

Flumes styles with flat bottoms (Parshall, Cutthroat, H, and Trapezoidal) do not suffer from upstream sedimentation in the way a Palmer Bowlus flume can.

Sensitivity to Upstream Conditions

For greatest accuracy, it is recommended that the channel or pipe upstream of a Palmer Bowlus flume is straight and without bends, dips, or elbows for at least (25) pipe diameters.

Other flumes require shorter straight runs (3-5 for HS / H / HL and 15 for Parshall) making them better suited to space constrained applications.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID