This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Drawbacks to Using Palmer Bowlus Flumes

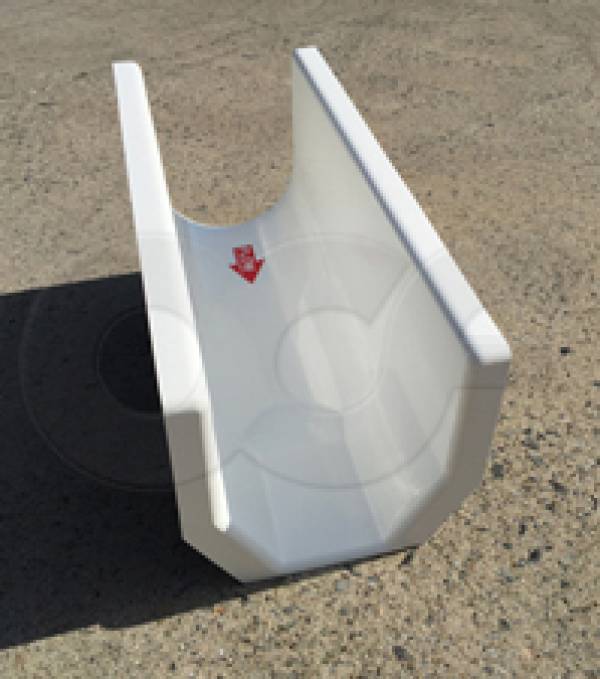

The Palmer Bowlus flume – quite possibly the second only behind the Parshall flume for measuring wastewater flows – suffers from a number of problems when it comes to its operational use.

The Palmer Bowlus flume – quite possibly the second only behind the Parshall flume for measuring wastewater flows – suffers from a number of problems when it comes to its operational use.

Some of the problems include:

- Proprietary design

- High minimum flow rates

- Solids passage

- Long upstream requirements

- Ramp height, level measurement, and point of measurement

Proprietary Design

Although the general design of the Palmer Bowlus flume has been standardized in ASTM D 5390-93 Standard Test Method for Open-Channel Flow Measurement of Water with Palmer Bowlus Flumes , the particulars of the design has not. Per D 5390, the Palmer Bowlus flume can be viewed as a CLASS of flumes – and not a fixed, defined style.

ASTM D 5390 goes so far as to observe that:

…there is no fixed shape for Palmer Bowlus flumes…

As such, the dimensions (and discharge characteristics) can and do vary from manufacturer to manufacturer. It should not be assumed that Palmer Bowlus flumes from different manufacturers are interchangeable or that the discharge tables from one manufacturer are accurate for another manufacturer’s flume.

High Minimum Flow Rates

The Palmer Bowlus flume was designed at the outset to measure sanitary flows in conduits and piping systems. The basic design assumption was that flows would not experience wide rate changes – that they would remain nice and average. Unfortunately, that has translated into relatively high minimum flow rates – generally higher than similarly sized Parshall flumes and definitely higher than HS / H and Trapezoidal style flumes.

Solids Passage

As discussed above, Palmer Bowlus flumes were not designed for low flow applications. An outgrowth of this is that, when used in applications where the flows are small but the solids content is high (or the solids are heavy), sedimentation can and does occur upstream of the throat ramp. These solids may not push through the flume even should the flow rates rise. Manufacturers have attempted to overcome this limitation by introducing alterante, rectangular cross-section throats (see the discussion of proprietary dimensions above), but thes are only marginally effective and dramatically restrict the range of flows the flume can accurately measure.

Long Upstream Requirements

The standard rule for upstream requirements for a successful Palmer Bowlus flume installation is that there should be 25 straight runs of upstream pipe / channel (no bends, dips, or elbows). For industrial / pre-treatment applications when a plant may be space constrained, it can be difficult to site the flume where it is both accessible to the operator and which meets the upstream conditions. Shortening the upstream straight run can lead to poorly distributed / unbalanced flows enter the flume – impacting the flume’s accuracy. To counteract this, flow straighteners and energy absorbers can be used for some applications, but they are not cure-alls for all applications.

Ramp Height, Level Measurement, and Point of Measurement

One problem that we run into again and again with operators is the backwater developed by throat ramp.

Some operators instinctively know that taking a level reading from the surface of the water the bottom of the flume will overread what the actual stage level is in the flume. This can lead to them trying to measure the level in the flume above the throat ramp which under-indicates the actual stage level as the throat is an area of drawdown as the flow accelerates through the flume.

Others realize that measuring over the throat isn't right and instead move upstream and measure from the water's surface to the floor of the flume (just like they would with a flatbottomed flume like a Parshall, HS / H / HL, Cutthroat, or Trapezoidal). Unfortunately this over represents the stage as it also includes the backwater developed by the throat.

Further, even when an operator knows to deduct the height of the backwater generated by the throat ramp, it is not uncommon for an operator not to know the height of the ramp. This is typically D/6, but not guaranteed to be so - see the proprietary design discussion above.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID