This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

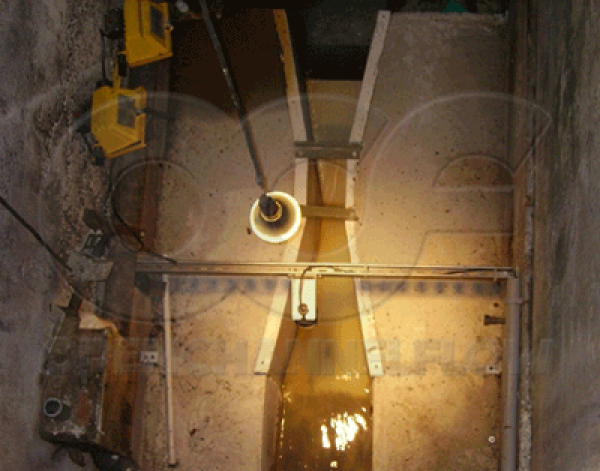

Fiberglass Parshall Flumes

Once found only at wastewater treatment plants, Fiberglass Parshall Flumes have spread to a variety of applications where other materials have traditionally held sway. The shift from traditional materials like concrete, mild steel, and wood – all used during the initial development of the Parshall flume – has been the direct result of the robustness, corrosion resistance, and dimensional accuracy of fiberglass.

When evaluating among materials it is important not only to consider the cost of purchasing the flume, but also the costs of installation and maintenance. When view as a whole, Parshall flumes from 1-inch to 144-inches in size are usually more economical and provide longer useful service lives than other materials.

Fiberglass vs. Concrete Construction

In wastewater treatment plants, fiberglass Parshall flumes are almost exclusively used for sizes from 1-inch to 120-inches. 144-inch Parshall flumes may either be fiberglass or concrete; while flumes from 180-inches and up are exclusively concrete due one-off, temporary molding costs for fiberglass construction.

The isophthalic polyester resins used in high quality fiberglass Parshall flumes are highly resistant to hydrogen sulfide (H2S). In contrast, in concrete Parshall flumes biogenic conversion of hydrogen sulfide into sulfuric acid occurs; ultimately converts the calcium hydroxide in concrete into calcium sulfate. The change both destroys the polymeric nature of calcium hydroxide and introduces a larger molecule into the concrete matrix, causing spalling of the exposed concrete surface.

In flow applications this means that over time the dimensions of a concrete Parshall flume change over time. Per JIS B7553 Parshall Flume Flowmeters, the dimensions of a Parshall flume must be within 1-1 1/2% of nominal for a Parshall flume to accurately measure flow. For very large Parshall flumes, 180-inches and up, some deterioration of the flow surfaces in the flume can be accepted given the overall size of the unit. For small flume, however, even small amounts of spalling or surface etching will result in the flume under reading the actual flow rate.

Fiberglass vs. Galvanized Steel Construction

Parshall flumes constructed of galvanized steel are still common in irrigation and water rights applications. In these applications, resistance to corrosion is not a concern and the flow streams are generally free of abrasive grit, debris, or stones, which might otherwise remove the protective galvanization.

While not as long as those experienced by fiberglass Parshall flumes, galvanized steel Parshall flumes can have decent service lives provided the flow surfaces are periodically inspected for rust and maintained with applications of cold galvanization paints.

Galvanized steel Parshall flumes weight more than their fiberglass counterparts. In a 9-inch size, a Parshall flume weights 65% more in galvanized steel. This increased weight may mean that the lower acquisition costs of a galvanized steel flume may be outweighed by an increase in installation costs.

Image: Wikipedia

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID