This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Fiberglass Shelter Ventilation Options

When it comes to ventilating fiberglass equipment shelters we have two options: active and passive. With each option, however, we have a number of choices and considerations.

Active Ventilation

The typical active ventilation set up in an equipment shelter is an exhaust fan (mounted high) and intake shutter (mounted low). The idea is to exhaust hot air (high) from the shelter while drawing in cool air (low). Activation of the fan is typically done by an exterior mounted switch or thermostat (or parallel combination of the two).

This arrangement works fine for most application, but for chemical (gas) feed / storage applications where the gas is heavier than air, the mounting of the fan / shutter need to be swapped (fan low / shutter high) or the operation of the fan and shutter need to be reversed (fan intake / shutter exhaust).

Where the environment / gas is corrosive it is common to have the fan operate in an intake mode (mounted high) and the shutter in an exhaust mode (mounted low). This keeps the electrical components of the fan protected as much as is practical – although it may still need to be of a corrosion resistant design.

Passive Ventilation

Where heat load is not as great a factor – or where chemicals are not being stored – passive ventilation may be desired. Passive ventilation is less expensive than active ventilation and it is suitable for sites where power is not available or expensive to bring to the site.

A typical setup for passive ventilation is to mount two adjustable louvers on the gable ends of the shelter to allow heat to escape the shelter. Adjustable shutter are preferred over fixed louvers as they can be closed off during colder months.

Fixed or adjustable, most louvers are designed in such a way that the rain should shed off them under most conditions. Coast installations may, however, require dedicated rain hoods over the louvers. In these cases the louvers are usually mounted on the eve sides of the shelter as there is typically not enough room at the gable ends to accommodate a rain hood (particularly above the shelter door which is also typically mounted on a gable end).

Hybrid Ventilation

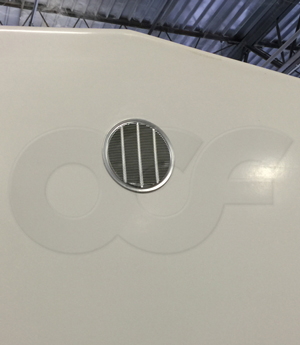

Straddling active and passive ventilation is hybrid ventilation. Here active ventilation is provided by wind action over a specially designed louver. While unpowered, the amount of ventilation is directly related to the wind speed over the shutter. No power, however, is needed / used.

The amount of ventilation is controlled by a plunger system on the inside of the shelter: push the plunger in and the amount of ventilation is reduced (or stopped altogether), pull the plunger out and the wind-powered ventilation is maximized (as is the passive ventilation if no wind is present).

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID