This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

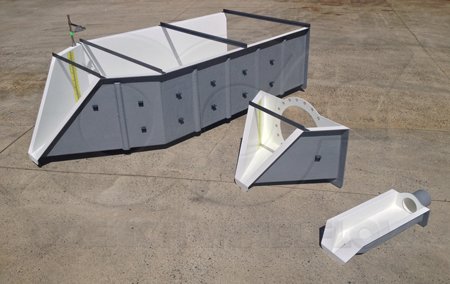

H Flume Configurations

H Flumes are one of the more versatile styles of flume when it comes to customization for site conditions. Versatility with the approach section length / layout mean that a wide variety of inlet conditions can be accomodated. While on the outlet side, drop box structures can acomodate a variety of piping configurations.

The basic H Type flume combines the self-cleaning properties of a flume with the low flow sensitivity of a sharp-crested weir. The flume consists of a flat floor (for the passage of solids), a uniformly converging inlet, and a rectangular cross-section.

The flume lacks a discharge section, so unmodified it requires free-spilling discharge off the end of the flume. The throat, at the discharge of the flume, is formed by sloping the top of the flume downwards in the direction of flow. The result is a truncated V-shape whenviewed in elvevation from the end of the flume.

To this basic shape a number of additions have been created.

Approach Sections

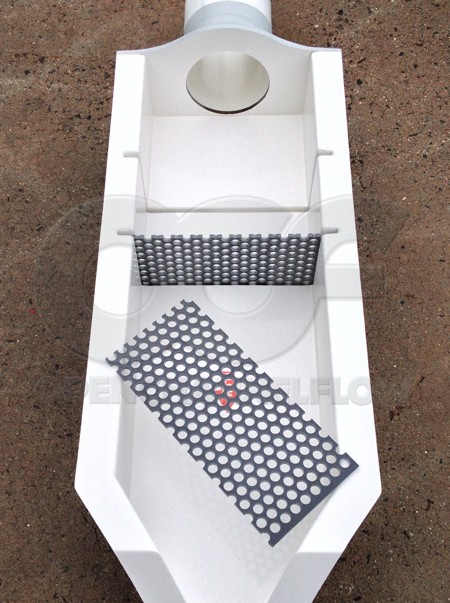

The approach section of a H type flume is nothing more than a straight, upstream continuation of the rectangular cross-section of the entrance of the flume.

This upstream section is usually between 3 and 5 D long (D = the maximum anticipated head, Hmax). The purpose of the approach section is to condition the flow into the flume so that it enters the flume in a controlled, well distributed, and uniform manner.

An advantage of the approach section is multi-fold:

- It allows a convenient location for pipe stubs / flanges to enter the flume

- It provides space for flow conditioning elements to be mounted

- It allows for multiple pipes to be combined for flume to measure

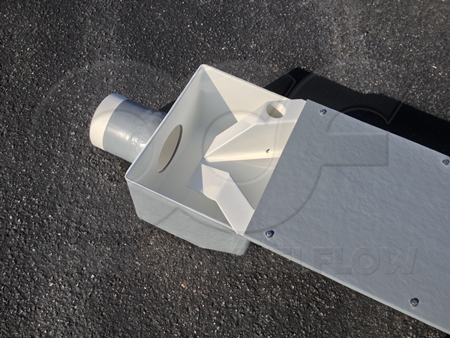

Outlet Drop Boxes

With a standard H Type flume, the flow simply spills off the end into the downstream channel. For many applications, this method, although sometimes inconvenient, is suitable. For other applications, there exists a need to transiton the flow into a downstream pipe. In those applications, a drop box can be added to allow the flow to be captured as it spills off the end of the flume and directed in to an outlet pipe.

Outlet drop boxes are usually molded or otherwise attached to the junction of the end of the approach section (when present) and the entrance of the flume. The discharge piping can lead the drop box either horizontally or vertically, depending upon the application needs.

When setting the elevation for horizontally discharging pipe, attention should be paid to the elevation of the water in the pipe relative to the floor of the flume. Using the floor of the flume as the zero reference elevation, the ratio of upstream level in the flume (at Ha) and the downstream level should not exceed 30% - and idealy the maximum downstream water level should be below the floor of the flume.

A further benefit of the outlet drop box is that it allows H Type flumes to be used in Fiberglass Enclosures and Packaged Metering Manholes - providing operations with an even greater selection of flumes to meet their flow monitoring needs.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID