This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Industrial Flow Monitoring / Sampling Stations

Those responsible for collecting and reporting industrial pretreatment discharge information (typically flow, pH, BOD, and temperature) are rarely dedicated professionals. Almost always, environmental discharge monitoring is just one of a laundry list of job duties they have to preform on a daily basis. This is a primary reason why engineered Industrial Flow Monitoring / Sampling Stations are such a good value for the industrial user.

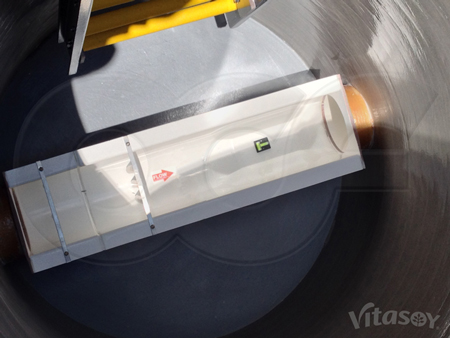

A typical station consists of two parts: fiberglass Packaged Metering Manhole from which flow data can be collected / samples drawn / parameters monitored and a pre-engineered fiberglass Equipment Shelter to house the flow meter, sampler, and parameter monitoring equipment.

A Packaged Metering Manhole factory integrates a flume, weir, or other primary device with the proper transitions to allow for accurate flow measurement. The configured primary device is then integrated into a fiberglass manhole; the result is a single piece, watertight corrosion resistant structure that not only provides accurate flow readings but also requires little to no maintenance.

For installations where the flow meter / sampler / parameter equipment can't be mounted inside an existing building near the metering manhole, a fiberglass Equipment Shelter is commonly used. Pre-engineered, these structure are plug and play - simply unload them, put them on a concrete pad, connect the power and you are done. These equipment shelters should ideally be placed right next to the metering manhole to allow the operators easy access to both sets of equipment (that in the manhole and that in the shelter) during calibration and maintenance.

One of the big problems that industrial operators face, but don't appreciate the gravity of, is when a flow meter isn't located near the primary device it is measuring. The greater the time it takes an operator to manually measure the flow in the device and then check this against the flow meter's reading, the greater the likelihood that the flow in the device has changed. The operator may, therefore, be calibrating their meter with an incorrect flow reading - always wondering why their flow readings aren't right even though they keeping "calibrating" their meter. Using a dedicated equipment shelter located next to the metering manhole - instead of trying to remotely mount the equipment in an existing building - can be a less obvious way of increasing reporting accuracy.

While there is a cost to factory integration (Packaged Metering Manhole) and pre-engineering (Equipment Shelter), these costs are more than offset by the end to end integration that a complete Flow Monitoring / Sampling Station offers.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID