This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Integrating Large Flumes into Packaged Metering Manholes

One of the oft-mentioned benefits Packaged Metering Manholes is the ability to integrate flumes and other structures that are larger than the manhole barrel diameter, but what exactly does this mean?

Background

For below grade applications – typically sanitary sewer mains or industrial pre-treatment discharges – flumes can be a useful way of measuring flows in non-full pipes.

Provided with end adapters to transition the flow into / out of the flume, the only question is how to protect / enclose the flume. Any solution must also take into consideration that operators will need access to take flow readings, calibrate instrumentation, and take samples.

Concrete’s relatively poor adhesion to fiberglass means that a flume cannot simply be cast with a concrete manhole or vault at the time of the manhole’s/vault’s construction. If concrete is to be used, the entire flume / end adapters / pipe stubs must be contained in the structure.

For any but the smallest flumes, this means that the concrete structure gets very long, very fast. For example, a 6-inch Parshall flume (a small to mid-sized flume for these applications) is 10-feet 1-inches [3.07 m] long. The problem gets worse as the flume gets larger – a 108-inch x 24-inch Cutthroat flume is 14-feet 10-inches [4.52 m] long.

Solution

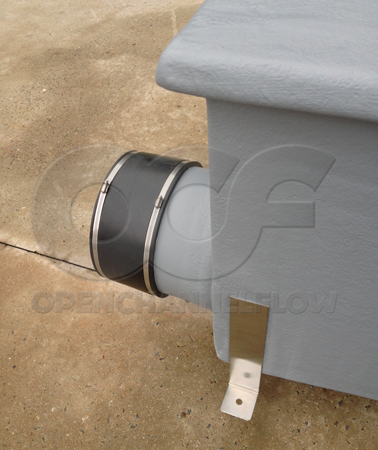

For fiberglass, the solution to the problem is simply. First, during construction, any parts of the flume or end adapter that will stick out upstream or downstream of the Packaged Metering Manhole barrel are reinforced and increased in thickness. The standard wall thickness of a flume is 1/4-inch [0.635 cm] – thinner sidewall construction is not recommended. This thickness is increased to a minimum of 1/2-inch [1.27 cm] with additional reinforcement of the sidewalls and floor as necessary.

After this, those portions of the flume extending beyond the Packaged Metering Manhole have a reinforced, watertight fiberglass cover laminated to them. The reinforced fiberglass cover is designed to withstand soil loads up to 150 lbs [68.0 kg per foot of depth, plus AASHTO H-20 loading when buried. While not all applications will experience H-20 loading, all flumes extending outside the barrel of the Packaged Metering Manhole receive this reinforcement.

The reinforced and covered flume is then laminated / bonded into the Packaged Metering Manhole barrel. The resulting structure is monolithic, watertight, and structurally sound.

With OSHA compliant fiberglass ladders, fiberglass gratings, and factory-installed fiberglass benches with molded-in non-slip surfaces, Packaged Metering Manholes provide customers with the greatest certainty of accurate flow measurement in a safe and secure environment for operators.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID