This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

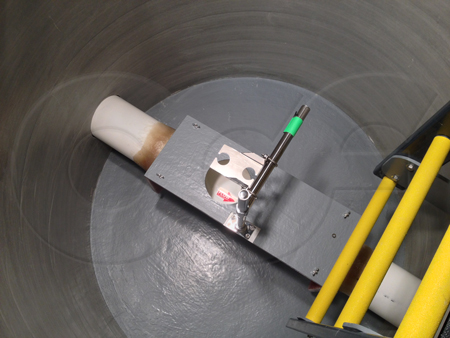

Pretreatment Monitoring Manholes

Publically owned wastewater treatment plants (POTWs) collect wastewater from homes, commercial and industrial facilities and remove harmful organisms and other pollutants so that the treated water can be returned to the environment without impact the receiving waters. As part of this collection and treatment, POTWs enforce discharge standards to the collection system in accordance with federal, state, county, and city regulations. Commercial and industrial users are required to control (or pretreat) their wastes to control organisms and pollutants which may interfere with treatment of the wastewater or which may pass through the treatment system and into the receiving waters.

As part of the pretreatment requirement, commercial and industrial users are required to measure the rate / volume of their wastewater discharge as well as to sample the discharge to ensure that the contaminants and pollutants do not exceed the levels specified in their discharge permit. Packaged Pretreatment Monitoring Manholes play a critical part in this measurement and sampling.

A Pretreatment Monitoring Manhole is typically a fiberglass manhole into which a flume or other primary device has been factory integrated. Factory integration provides confidence to the POTW or enforcement agency that the device has been properly installed. For the industrial user factory integration also means single source responsibility as installation is greatly simplified and there are clear lines of responsibility / scope of supply.

At the core of each Openchannelflow Pretreatment Monitoring Manhole is a high strength manhole barrel. These barrels are meet the strict requirements of ASTM D 3753 (Standard Specification for Glass-Fiber-Reinforced Polyester Manholes and Wetwells), with each barrel rated to withstand AASHO H-20 loadings.

Into this barrel a primary device – usually a flume – is integrated. Factory integration means that the device is properly installed, is level in the manhole, and it also allows flumes and other measurement structures much larger than would otherwise be able to integrated into standard manholes and vaults to be used.

Covers and tops are integrated into the top of the Monitoring Manhole to fit the application, with H-20 reducers for traffic locations, domed fiberglass tops for non-traffic / grassy areas, and flat aluminum tops for low profile or foot traffic areas. For custom applications, flat fiberglass, open top, and grating top configurations are also available.

Depending upon the height of the manhole, a stainless steel reinforced fiberglass ladder may be provided as part of the Monitoring Manhole structure.

In short, Pretreatment Monitoring Manholes provide a factory integrated, drop-in-place solution to the need of commercial and industrial customers to monitor their pretreatment flows. They also provide a safe and convenient place from which monitoring agencies can perform their duties.

Image: City of Atlanta Office of Watershed Protection / Industrial Pretreatment Program

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID