This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Raising Parshall Flumes to Overcome Poor Entrance Conditions

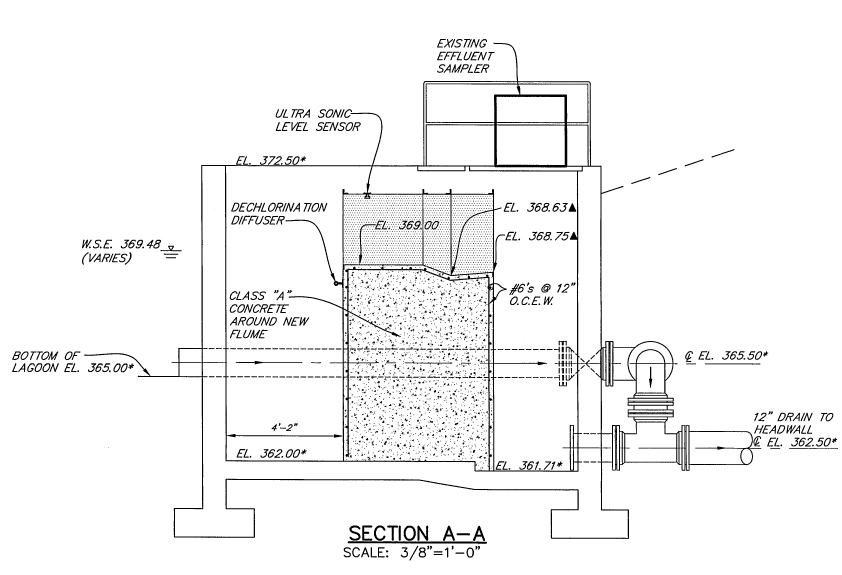

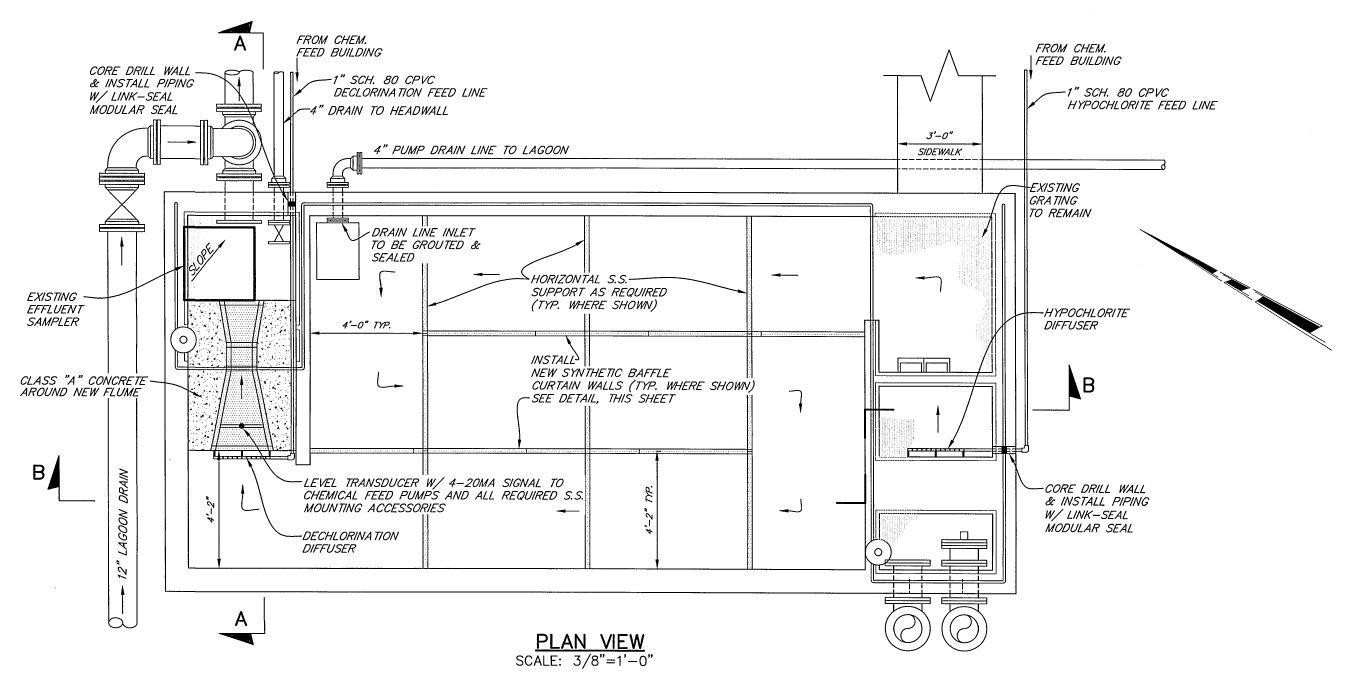

In space constrained applications it can be difficult to get the upstream conditions necessary for accurate flow measurement with a Parshall flume. While flow conditioners - usually perforated plates or stainless steel fingers - can be used in some installations, they aren't appropriate for all of them. For installations where flow conditoners aren't appropriate, and where there is sufficient head available - it may be more practical to simply raise the flume above the approaching channel floor.

Raising the flume creates a backwater effect that slows and conditions the approaching flow. The flow is slowed by the upsteam pool and rises up before it enters the flume.

To be effective, the Parshall flume should be set at least 2 times the height of the converging section. Lower and there is the chance of turbulence being generated as the flow transitions from a vertical rise to a horizontal run into the entrance of the flume.

By raising the flume, not only can straight run requirements be minimized, but bends, dips, and elbows - normally generators of turbulence and poor velocity profiles - can occur upstream without impacting the accurate operation of the flume. Likewise, the EPA recommendation of 5-20 downstream throat widths of straight channel is greatly reduced / eliminated.

Finally, when a Parshall flume is used in an elevated installation a shorter - Montana or USGS - style can be used. This can save not only space, but cost for the operator.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID