This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Underflow vs Overflow vs Flow-Through Baffles in Weir Boxes

For a weir box to provide accurate flow measurement, the flow approaching the weir needs to be well distributed as it enters the weir pool. Unfortunately, weir boxes are usually used to measure flows in gravity pipe systems.

For a weir box to provide accurate flow measurement, the flow approaching the weir needs to be well distributed as it enters the weir pool. Unfortunately, weir boxes are usually used to measure flows in gravity pipe systems.

So how do we reconcile these two?

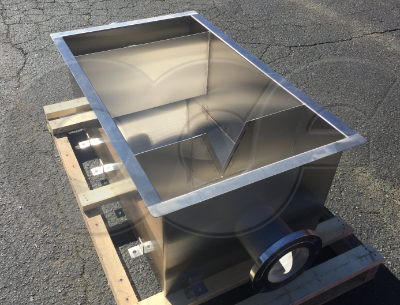

The answer is upstream baffles. Properly configured, baffles slow the flow as it enters the weir box and spreads it evenly across the width of the weir box.

When the flow enters low on the weir box (relative to the weir crest elevation), an overflow baffle is used. Usually when an overflow baffle is used, there is an underflow baffle downstream so that the flow has to rise up before going over the weir crest.

When the flow enters high on the weir box, an underflow baffle is used. A second baffle is not normally used downstream of an underflow baffle as the intent is use the weir pool to dissipate any additional energies / turbulence – and forcing the flow to rise up to go over the weir crest accomplishes this. Additionally, surface turbulence is contained upstream of the weir pool.

A side benefit of the underflow baffle is that floating solids can usually be contained upstream of the weir pool – reducing weir crest maintenance.

Occasionally neither of these two baffles are appropriate for a site’s particular requirements. Here flow-through baffles (perforated plates) may be used. The plates – usually used in sets of two or more – help to normalize the velocity profile by forcing flow into parallel lines prior to entering the weir pool.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID