This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Understanding Packaged Metering Manholes

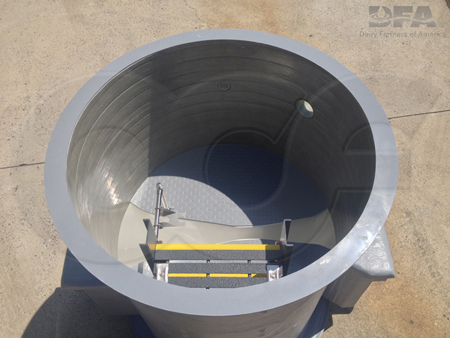

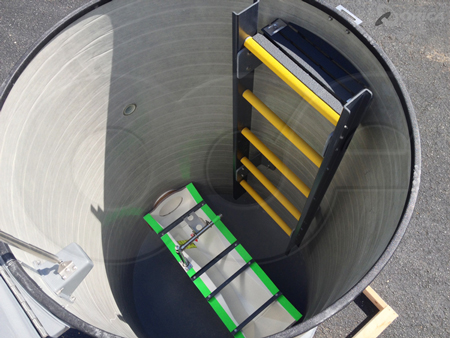

In its simplest form a Packaged Metering Manhole (PMM) consists of a primary device (typically a flume or weir) molded into a fiberglass (FRP) manhole. By directly factory integrating the primary device, a single-piece, drop in-place flow monitoring solution is created.

Packaged Metering Manholes are watertight, corrosion resistant and can easy installed as part of new construction or as a retrofit when there is a need to measure below grade flows.

Installation of a Packaged Metering Manhole is straight forward. After selecting a site that provides good flow conditions, the area is excavated. The exposed sewer line can then either be cut or excavated around to allow the pouring or setting of a concrete pad. In applications where the line can only be out of service for a short time, the Packaged Metering Manhole can be mounted off-site on a precast slab and then the mounted assembly can be taken to the installation site. The concrete pad serves both as a level surface for the Packaged Metering Manhole as well as an anchor against the buoyant forces acting on the manhole.

Once in place and set on the slab, the Packaged Metering Manhole is shimmed so that the primary device is level. The manhole is then connected to the sewer line by means of flexible Fernco couplings, caulking collars, or flanges. With the manhole secured both to the pad and sewer line, the excavation is back filled. What is left is an easy-to-use, highly accessible flow monitoring station.

At a prepared site, the installation downtime can be kept to a minimum. Off-site mounting of the Packaged Metering Manhole to a concrete slab can further speed the installation process.

Now secured, all that is needed is for a bench to be formed inside the manhole. The bench allows any water that backs up into the manhole to drain out once the backup is cleared and its forming can take place after the end connection have been made of the sewer line needs to be back up and running.

Typically forming a bench means that the void space inside the manhole between the flume and the manhole barrel is filled with sand and capped by grout. To make the installation process even easier - and to provide a safer workspace for operators - Openchannelflow offer factory molded, fiberglass benches. The benches have a molded-in, low maintenance diamond plate surface that provides a maximum of operator convenience and safety.

Openchannelflow Packaged Metering Manholes are provided with a smooth, light colored interior surface to provide a workspace that is clean, safe, and easily maintained.

Openchannelflow Packaged Metering manholes are built to meet the latest edition of ASTM D3753 Standard Specifications for Glass-Fiber Reinforced Polyester Manholes. They are easy to install, easy to maintain, and are designed for long service lives under even the most demanding of conditions.

Openchannelflow Packaged Metering Manholes are available with:

- 4', 5', 6', and 8' diameters

- Burial depths up to 35'

- A wide variety of flume and weir styles and sizes

- Multiple top styles including hinged fiberglass, aluminum pedestrian, various diameters of H-20 reducers, fiberglass grating, and open tops

- OSHA complaint fiberglass ladders

- A wide variety of flume accessories (mounting brackets, stilling wells, covers, gratings, etc.)

- Lighting, vents, equipment shelves, and more

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID