This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Upstream / Downstream Pipe Slope and Straight Runs for Flumes

Time and again, we get questions on pipe slope and straight run requirements from customers looking to connect flumes to piping.

The questions that come up are usually:

- What is the maximum upstream pipe slope I can come into a flume with?

- How many straight runs of pipe do I need upstream of a flume?

- What should the downstream slope be?

- Are there any downstream restrictions when installing a flume?

Upstream Pipe Slope

For flumes with end adapters (Parshall, Palmer Bowlus, HS / H / HL, Trapezoidal, Cutthroat, and Montana), the chart below can serve as a guide.

| Maximum Recommended Upstream Slope By Line Size | |

| 4 to 6-inches [10.16 to 15.24 cm] | 2.2% |

| 8-inches [20.32 cm] | 2.0% |

| 10-inches [25.4 cm] | 1.8% |

| 12-inches [30.48 cm] | 1.6% |

| 15-inches [38.10 cm] | 1.5% |

| 18 to 21-inches [45.72 to 53.34 cm] | 1.4% |

| 24 to 30-inches [60.96 to 76.20 cm] | 1.3% |

Remember that flow entering a flume must be subcritical (Fr<1) and that above Fr = 0.5 wave action may occur. As a result, the recommended pipe slopes are generally half of those above. Flow rate, pipe size, and pipe material all come into play, but the above numbers are a good starting point.

RBC flumes are not available with end adapters to connect them to piping so discussions of upstream pipe slope do not apply to them.

Upstream Straight Run

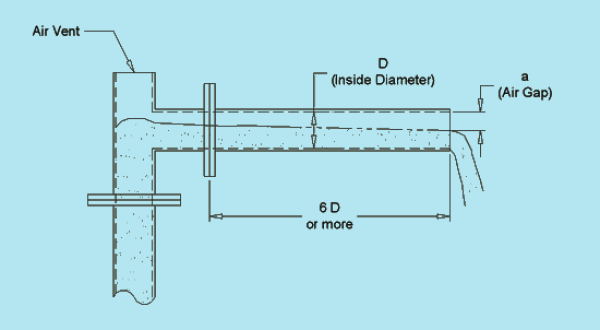

The rule of thumb for how much upstream straight run pipe is required is that there should be not bends, dips, elbows, etc. upstream of the flume for 15 pipe diameters.

Shorter distances may be possible if the flow in the pipe is small in relation to the pipe’s carrying capacity, but understand that this is a rule of thumb only and it is based upon actual application experience.

Openchannelflow does offer flow conditioning devices (energy absorbers / perforated plates / tranquilizing racks) to help correct poor flow conditions, but in general their availability should not excuse the installer from taking the necessary precautions in siting a flume.

Accurate flow measurement requires, in part, proper upstream conditions.

Downstream Pipe Slope

The requirements for downstream pipe slope are not as stringent as they are for upstream pipe slope. The downstream pipe slope should simply be as great, or greater, than the upstream pipe slope. The goal here is no to have flow back up into the flume.

Downstream Pipe Size / Restrictions

Similarly, the downstream pipe should be at least as large as the upstream pipe. Any change in direction should take place at least 5 pipe diameters (and potentailly up to 20) after the flume.

Combinations of downstream pipe slope and pipe size can be used to achieve the desired goal on not backing flow up into the flume (i.e. the pipe slope and size can be increased, allowing a change in pipe direction closer than 5 pipe diameters).

Understand that most flumes do not have submerged flow equations, so any submergence due to poor downstream conditions may not be readily correctable.

Source: Teledyne ISCO Open Channel Flow Measurement Handbook

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID