This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Wastewater Flow Monitoring

No two ways about it...

wastewater can be a pain to accurately measure. The environment is corrosive and humid; while the flow itself can experience wide swings due inflow and infiltration. Wastewater is usually carried in non-full open channel pipes. Measuring in these pipes is considerably more complex that in closed pipe systems.

Traditional Method

The traditional method of measuring wastewater flows is through the use of a flume and an ultrasonic flow meter in a flow manhole (concrete vault / manhole or fiberglass packaged metering manhole). The combination is reliable and usually requires low maintenance.

Maintenance

As a fixed structure, flumes have no moving parts. Maintenance is usually confined to ensuring that sediment and debris does not accumulate upstream of the flume (common with Palmer Bowlus flumes). The downstream channel must also be kept free of sediments and debris in order to minimize submergence of the flume and surcharging of the measurement structure. Entry into the metering area may require confined space equipment and purpose trained personnel.

Now most structures where flumes are used are permanent in nature; flow trending data is the goal and temporary data loss is not as critical. This is not to say that no maintenance is required for the ultrasonic sensor mounted above the flume. Depending upon the site, calibration and maintenance on a quarterly or semi-annual basis. This maintenance is common for flow sensors – whether they be ultrasonic level sensor of the type used with flumes or of the above-the-channel meters that have recently come on the market (including the Hach / Marsh-McBirney’s FloDar or Teledyne Isco’s LaserFlow). Sensors need to be kept free of condensation and debris. Additionally, it is necessary to periodically verify the calibration of the sensor.

Understanding Flow Data

When used for billing purposes, it is important to have personnel who understand not only the equipment, but also the patterns and cycles of the flow. Experienced personnel can diagnose and correct data problems as well as calibrate and maintain the measurement equipment.

Two common problems that can arise in the collection of flow data are sensor drift and site surcharge.

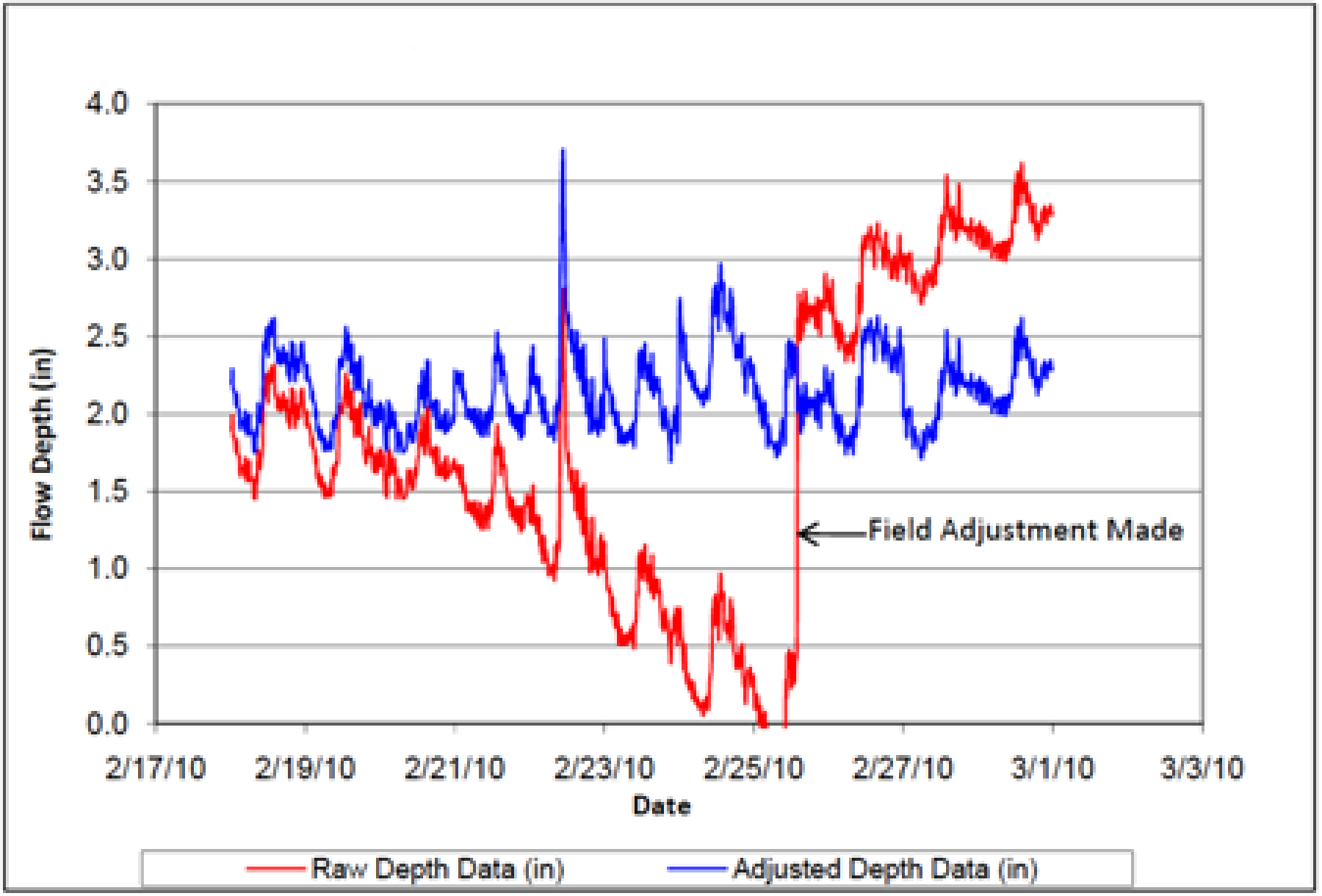

Sensor drift is where, over time, the sensor begins to drift in from its calibration. Under normal conditions, the sensor will drift in one direction – higher or lower. If, however, the sensor is beginning to fail, the readings may swing one way for some time and then the other. These swings, either in one direction or back and forth, are independent of the actual flow and the raw flow data can be adjusted to minimize the discrepancy.

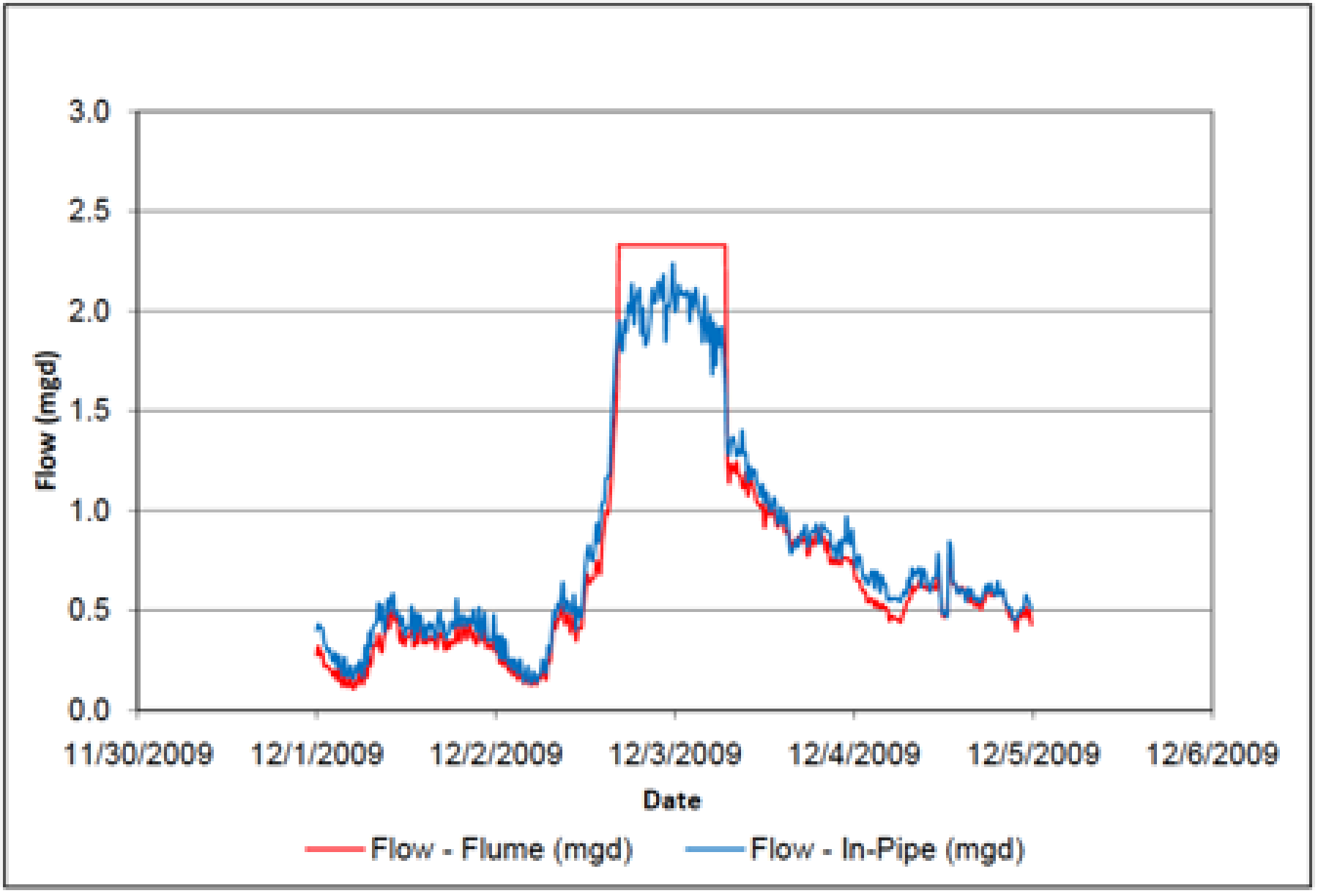

Surcharging occurs when a downstream restriction back flow up into the metering structure. Flow rises and rises until the data collected by the flow meter flat lines. The meter flat lines as the level of the wastewater rises in the sensor’s deadband (blanking distance).

Once the surcharge condition subsides, the water level drops, eventually dropping out of the sensor’s deadband. At that point the flow meter again begins to capture variations in the water level.

Source: Adapted from Wastewater Flow Monitoring Pitfalls: Common and Uncommon Problems and Solutions

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID