This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

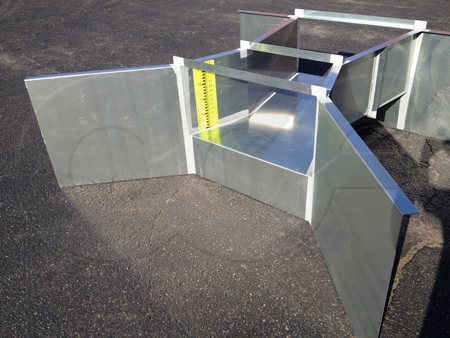

Water Rights Flumes

As State Engineer’s Offices become more concerned over accurate measurement of water rights withdrawals, flow-measuring devices are becoming mandatory. These flow-measuring devices typically take shape as flumes – with the Parshall and Cutthroat flumes being most common. Both flumes were developed to solve the particular needs of irrigation applications and are well suited to the task. Of the two, the Parshall flume is by far the most common.

Flume Types

Parshall Flumes

The Parshall flume is the original flume developed for water rights and irrigation flows. Development of what would become the Parshall flume began in 1915, with the initial studies published in 1921. Over the years, additional sizes of Parshall flumes were added to meet the growing uses for the flume.

From the top, the flume posses and elongated hourglass design – contracting at the inlet to a straight throat before expanding again to the outlet. As flow passes through the flume, it is accelerated by a drop (and partial) recover in the throat and discharge section.

This drop can limit the use of the Parshall flume when flat gradients are involved or when upstream / downstream hydraulics can only be moderately adjusted.

22 standard sizes of Parshall flume are available; however as the flumes are not scale models of each other, interpolation of intermediate sizes is not possible and any non-standard size or dimensions must be calibrated.

Cutthroat Flume

In the 1960’s the development of what would ultimately become the Cutthroat flume began. Funded by the U.S. Department of the Interior’s Office of Water Resources Research, researchers working through the Utah Water Research Laboratory set out to develop a flume that was suited to measuring flows on flat gradients and which operated satisfactory under both free and submerged flow conditions. The result was a flume that was simple in shape and construction, but which met the project’s goals.

Possessing a flat bottom, the Cutthroat flume is easy to install into existing channel without the need to raise the flume above the channel floor (increasing upstream head) or adjusting downstream hydraulics. Vertical sidewalls give good resolution over the full range of flows.

16 standard length / width combinations of Cutthroat flumes have been developed. Unlike the Parshall flume, however, although additional, intermediate sizes can be developed without the need for time consuming (and costly) flow rating. The flat floor and standard constriction / expansion ratios of the inlet and outlet of the flume allow for the development of additional sizes.

Materials of Construction

Two materials of construction are common for water rights flumes: galvanized steel and fiberglass. Galvanized steel is the more common of the two materials – with about 3 of every 4 water rights flumes constructed of it.

Galvanized Steel

Galvanized steel flumes are typically 2/3 to 3/4 of the cost of a similar flume in fiberglass, but is considerably heaver and requires more maintenance than fiberglass flumes. Fiberglass flumes are lighter, cost more, and are – generally – more dimensionally accurate than galvanized steel flumes. Also, unlike galvanized steel flumes where weld points need to be periodically inspected and touched up with cold galvanization, fiberglass flumes are virtually maintenance free.

In selecting a galvanized steel flume it is important to that the manufacturer not only understand the various aspects of the construction of the flume, but also the proper application of the flume. Small flumes – those with throat widths smaller than 6-inches [15.48 cm] are commonly constructed from 14-gauge sheet. Large flumes (those with throat widths from 6 to 96-inches [15.24 to 243.8 cm]) should be constructed from 12-gauge sheet. Above 96-inches [243.8 cm], 7-gauge sheet should be used.

As galvanized flumes get larger, external stiffening ribs should be added down the sides and across the bottom of the flume. In particular, the floor of the flume should be supported by ribbing just at the entrance / exit of the throat section.

Fiberglass

Fiberglass flumes above 3-inches [7.62 cm] in throat width should have external stiffening ribs laminated to the exterior of the flume. Flumes 72-inches [182.9 cm] and larger should structural foam and steel tubing encapsulated in the floor. Laminate thickness should be 1/4-inch [0.635 cm] for flumes from 1 to 48-inches [2.54 to 121.9 cm]. Larger flumes should have a minimum laminate thickness of 3/8-inch [0.9525 cm].

Fiberglass flumes are 30-50% more expensive than similarly sized galvanized steel flumes, but are also about half the weight. As a result, they are typically easier to install than galvanized steel flumes, as they require less manpower and lighter duty equipment. Sectioned or multi-piece construction makes moving fiberglass flumes into position easier and the nature of fiberglass construction means that a wider range of options and accessories can be directly integrated into the flume than can be readily accommodated in galvanized steel construction.

As fiberglass flumes are constructed on specially built master molds, they tend to be more dimensionally accurate and more uniform than the one-off construction of galvanized steel flumes.

Flume Sizing

Half or reduced height flumes are more common in water rights applications than with any other types of applications. Irrigation ditches that are flat, wide, or a have relatively short channel banks are all candidates for reduced height flumes.

In choosing a flume size, it is generally recommended that you choose a size that is not too conservative (i.e. one that just handles your allotted right). Larger flumes provide more flexibility in site selection and allow for peaking factors that smaller flumes will not allow. During free river conditions – depending upon your right and local law - you may be able to divert a full ditch of water – an amount of water that may be many times more than your total right(s).

Image: Western Slope Rural Living

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID