This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

What Are Packaged Metering Manholes?

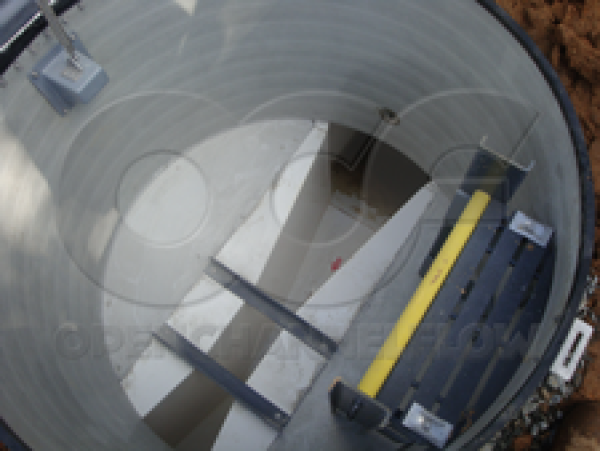

A Packaged Metering Manhole (PMM) is a factory-integrated fiberglass manhole that mounts a flume, weir, mag meter, or other primary device to allow a user to measure or sample flows from full or non-full pipes.

A Packaged Metering Manhole (PMM) is a factory-integrated fiberglass manhole that mounts a flume, weir, mag meter, or other primary device to allow a user to measure or sample flows from full or non-full pipes.

Components of a Metering Manhole

At its most basic a Metering Manhole consists of:

- Manhole tube

- Top

- Primary device (flume, weir, mag meter)

- End connections (pipe stubs or flanges)

- Base

The manhole tube can also be supplied with a range of accessories, including: access ladders, vents, benching, cabling couplings, shelfs, and operator platforms.

Depending upon the primary device, stilling wells, flow meter mounts, gratings / covers, and other accessories can be mounted.

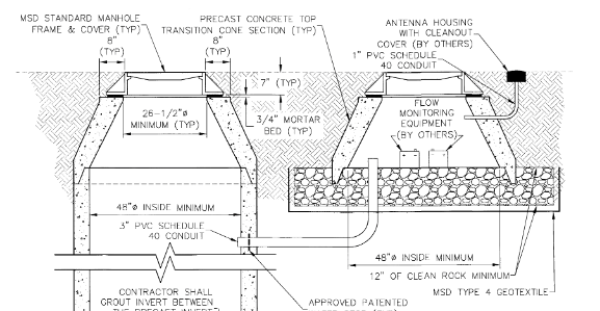

How to Install a Packaged Metering Manhole

Metering Manholes are extremely easy to install:

Metering Manholes are extremely easy to install:

- Excavate the site, exposing the line the manhole it to be connected to.

- Pour a concrete pad

- Divert / stop flow through the line

- Cut the line

- Lower the manhole onto the pad

- Connect the manhole stubs / flanges to the line

- Secure the manhole to the pad

- Backfill the excavation

For a step-by-step walkthroughs on how to install a metering manhole, take a look at:

Installing a metering manhole is a simple as Dig It! Drop It! Done!

Metering Manhole Advantages

Depending upon whether you are a consulting engineer, installing contractor, or operator, Packaged Metering Manholes have a number of distinct advantages over other flow metering approaches.

In general, the advantages are:

- Single-Source Responsiblity

- The primary device is factory integrated into the manhole - no finger pointing between subcontractors.

- Accuracy

- Properly installed primary devices (and reduced inflow) mean that accurate measurements can be taken

- Longevity

- Installed lifespans are typically 25+ years

- Reduced inflow

- Measure and quantify only the flow going through pipe - not that spilling into the manhole

- Environmental

- Watertight, corrosion resistant construction makes it unlikely that a metering manhole will ever experience a spill or leak due to failure of the structure

- Economics

- Higher initial material cost is more than off-set by installation and life-cycle costs

- Usability

- Packaged Metering Manholes are highly customizable - allowing operators to configure them for maximum usability. They require little more than a periodic wash down to maintain them. They provide excellent operator access entering / exiting the manhole as well as working inside with the primary device.

Metering Manhole Drawbacks

The only true drawback to a Packaged Metering Manhole is the higher upfront manhole cost - usually 25% more than concrete construction. However, as the Packaged Metering Manholes are turn-key systems (and are not susceptible to Microbial Induced Concrete Corrosion (MICC)) single-source responsibility alone more than outweighs any difference in the initial costs.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID