This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Wing Wall Materials for Flumes

Wing walls are nothing more that flat (typically) walls that extend from the channel banks to the flume. Their purpose is to direct flow into the flume in a controlled manner.

As they are not directly used to measure the flow in the flume, wing walls do not need to be held to the same dimensional tolerances that the flume itself needs to maintain. As a result, wing walls can be fabricated from whatever material is most handy – so long as it is watertight and relatively smooth. They do not necessarily have to be made from the same material as the flume.

In agricultural, stream gauging, and watershed applications it is common to see wing walls made from railroad ties or galvanized sheet. Both materials are readily available and should be able to be locally sourced.

Short-term stream gauging / watershed installations can also use sand bags, plywood, or packed earth to form wing walls. Note that if packed earth is used, it should be covered by a waterproof material so that erosion of the wing walls does not occur. If erosion does occur, flow may bypass the flume or the flume may settle out of position.

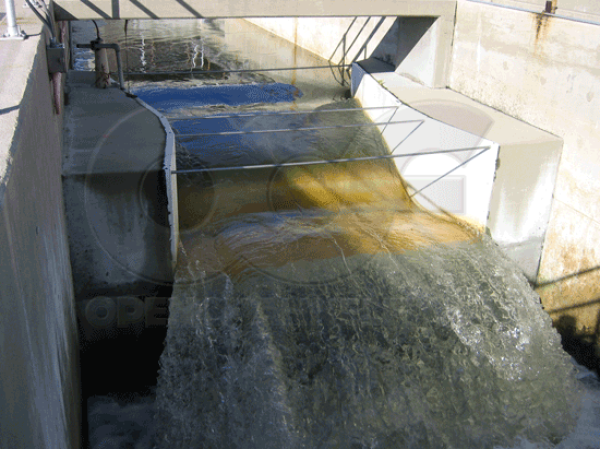

For more permanent installations, concrete is also used on irrigation and surface water flows. Concrete is relatively cheap, although it does require more site access than lumber or galvanized wing walls, so it is not suitable for remote or difficult to access sites.

At wastewater treatment plants, wing walls are almost always constructed from concrete or fiberglass. While we offer it as an option for all of our flumes, fiberglass wing walls do not necessarily provide better flow conditioning and many times cost more than site poured concrete walls.

One advantage that fiberglass has, though, over concrete is that radius inlet wing walls are readily available. Radius wing walls have been shown to be much less prone to the wave-trough phenomena that can develop where the inlet wing wall meets the inlet of the flume’s converging section.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID