Case Study

Konkola Sectioned Stainless Steel Cutthroat Flumes

Customer

Konkola Copper Mines Plc, Zambia

Background

The Konkola mine is situated in Chililabombwe, approximately 26 kilometres north of Chingola, and is the most northerly of the KCM's Zambian Copperbelt mines. These mining operations exploit the Chililabombwe ore body by underground methods. Shaft depths exceed 1,010 meters below the surface.

Problem

The Konkola mine is one of the wettest mines in the Zambian Copperbelt, with inflow volumes of approximately 400,000 m3 of water per day. The water from all pump stations is channeled through sumps for settling and sedimentation before clear water is pumped to the surface for discharge into the Kafue River. Accurate flow measurement is essential to the treatment and discharge of these flows, but the high level of abrasive solids combined with very limited shaft access made this difficult.

Solution

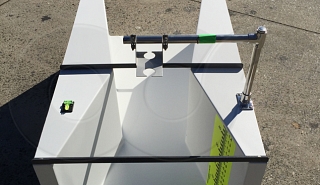

Over a period of several months, Openchannelflow worked closely with Konkola’s engineering department to develop a solution to the problem. After the initial selection of Cutthroat flumes to fit the existing channels well and flow rates, attention was paid to the material of construction. Openchannelflow knew the standard fiberglass construction wouldn’t withstand the abrasive grit suspended in the flow stream, so alternative materials were considered. After evaluating several lining materials for fiberglass construction flumes, Openchannelflow settled on T-316 stainless steel construction. T-316 stainless offered strength, rigidity, chemical resistance, and, most importantly, abrasion resistance.

The next challenge was getting the flumes down the access shafts to the installation sites. A multi-pieces approach was used – splitting the Cutthroat flumes into two or more pieces for ease of handling. All of the Cutthroat flumes were with factory connected and bundled with spare connection hardware for overseas shipment. Installation was smooth and Konkola benefitted from Openchanneflow’s foresight in providing spare connection hardware (there is no local source for replacements).