This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Case Study - Bureau of Reclamation - Field Assembled Cutthroat Flume

Case Study

Case Study

Watershed monitoring in an inhospitable environment

Customer

U.S. Department of the Interior – Bureau of Reclamation

Background

The Bureau of Reclamation was tasked with conducting a basin-wide effort to define the problems, identify solutions, and options relating to protecting and increasing water supplies and improving the health of a high mountain watershed.

Problem

The terrain in which monitoring needed to conducted was extremely rugged and nearly inaccessible. Only two options existed for getting a flume into place: helicopter and ATV. Additionally, the flashy nature of the streambed resulted in higher sediment loads than those experienced by a typical flume installation. The sediment and debris was particularly abrasive in nature so fiberglass was ruled out as a material of construction. Cost was also a concern given the limited lifespan of the project.

Solution

Openchannelflow worked with Bureau of Reclamation hydrologists in the initial selection of the flume. Taking the Bureau of Reclamation’s preliminary flow date and combining it with the site and sediment load information; Openchannelflow determined that a Cutthroat flume would be the best fit. The Bureau of Reclamation reviewed the suggestion and agreed.

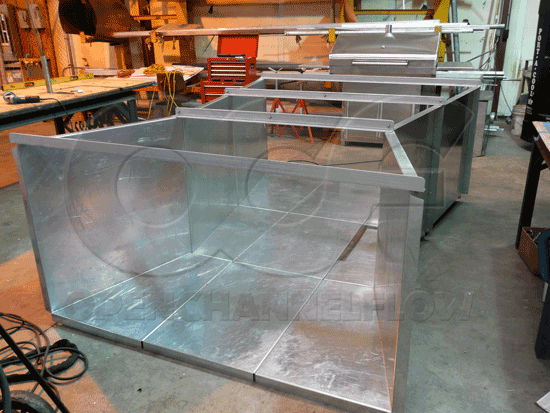

The next issue to tackle was that of portability. The Cutthroat flume selected was a 108-Inch L x 72-Inch W size – far too large for a single ATV to haul. The need to control costs eliminated a helicopter lift of the flume. Drawing upon its previous experience with space-constrained projects, Openchannelflow recommended the flume be constructed in nine segments for field assembly. Mock-ups of the more complex flume pieces were made to verify that the Bureau’s ATV would be able to safely secure and transport the flume to the site.

Once this was completed, Openchannelflow got the flume into production to meet the Bureau’s tight timeline. Finally, piggybacking the flume with another order already heading out west saved the Bureau already tight funds.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID