The old adage of taking measuring twice and cutting once has never been so appropriate as it is when determining the depth of a fiberglass manhole.

Although fiberglass manholes (FRP) posses a wealth of benefits; modularity is not one of them. Because all of the elements are laminated together to form a single, monolithic and watertight unit, once the components are molded in, they are extremely difficult to change.

Flow rates and line sizes are relatively easy to determine for most applications, but manhole depth can sometimes be a little trickier.

Understanding Manhole Top Styles

There are three top styles for fiberglass manholes: domed fiberglass, aluminum hatch, and highway-loading. The depth for each top style is determined differently, so it is important to understand how the manhole is to be used and what the prevailing site conditions are.

Domed Top

The domed top is the most common style for Packaged Metering and Grinder Manholes. A reinforced, molded fiberglass cover is attached to the top of the manhole barrel with a stainless steel piano hinge. The fully opening action makes domed top manholes the easiest to enter / exit.

Because the domed top rests on the top edge of the manhole barrel, the seal between the top and the barrel is not intended to be watertight. As such, the top of the manhole is sized to be 12 to 18-inches [30.48 – 45.72 cm] above the surface grade. For applications where standing water may be present, the top of the manhole may be set even higher.

With the domed top sitting 12 or more inches above the surrounding surface grade, domed top manholes are only suitable for grassy (non-traffic, pedestrian and vehicle) areas.

The most common problems with applying domed top manholes are not allowing enough space above the surface grade or regrading of the installation area. Domed top manholes that are set too low commonly experience inflow (surface water entering the manhole) and are susceptible to damage. While extensions are available to retroactively increase the depth of the manhole, its better to thoroughly consider the area the manhole is to be installed in, including future plans for the area.

The above should not be taken as a blanket recommendation to oversize the depth of domed top manholes. Manholes that stick too far up can also be a problem. While not as common as undersizing the manhole, we have seen several instances over the years where customers have to construct platforms to access manhole openings. Too much height, although undesirable, is relatively easy to fix in the field, but should be avoided nevertheless.

Aluminum Hatch

The pedestrian loading aluminum hatch top is the least common of the three top styles available for fiberglass manholes. Here an aluminum hatch is mounted to a fiberglass surround at the top of the manhole. The hatches are generally designed to be flush with a sidewalk or other foot traffic area.

Making sure the finished area around the aluminum hatch is flush with the top of the manhole can be challenging. A minor difference when determining inverts may mean that the top of the manhole sticks up above the surrounding path or sidewalk, creating a potential trip hazard.

A better application of the pedestrian loading aluminum hatch is next to, but not in the direct line of traffic. Off to the side, the hatch presents a minimal trip hazard and if the top sticks above the surrounding area an inch or two, it isn’t a problem.

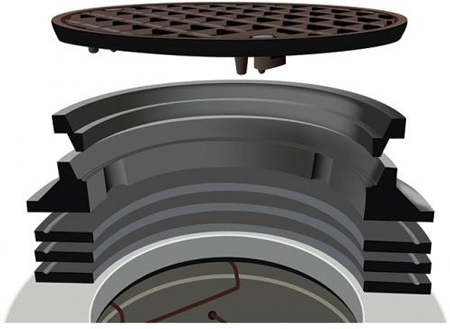

Highway Loading

The highway-loading top most closely resembles the standard concrete manhole. Here the shoulder of the reducer is set to be 10 to 12-inches [25.4 – 30.48 cm] below the finished road / surface grade. This space allows for the installation on a cover and frame system, as well as any grade rings necessary to bring the installation flush with the finish grade.

Generally speaking, making a highway-loading manhole too short isn’t a problem – more grade rings can always be added. Making a highway-loading manhole too tall is another story.

If there isn’t enough depth between the finish grade and the reducer shoulder, it may not be possible to add the necessary frame and cover system. Also, if the depth is too great, the reducer and part of the manhole barrel may stick up above the finish grade.

Should this happen, the only solution is to cut off the reducer and excess manhole tube and then laminate a new reducer to the modified manhole. Done in the field or back at the factory, this modification isn’t cheap due to the labor needed to resize the manhole and the cost of the replacement reducer.

- The most common error that we see when using fiberglass manholes is some times grading plans change without consideration as to how they impact the manhole depth, other times customers forget to allow the recommended distance above the surface grade.

- When sizing a fiberglass manhole it best to take your time and verify the actual and intended elevations. Double-checking these can save you time and money downs the road.

Image: Hamilton Kent