Ultrasonic Mounting Brackets

Ultrasonic Mounting Brackets

What makes our mounting brackets different?

We often talk about how OCF tried to sweat the small things. One of the items that we have focused on is our flow meter sensor mounting brackets. Many of the designs currently on the market show, what we believe to be, a "good enough" philosophy - that the brackets hold the sensor, but little thought was given to how easy the brackets are to use by the operators.

In designing our ultrasonic brackets we tried to work back from what the operator needs the bracket to do - put the sensor in the right place - to how we are going to do it. Our approach resulted in a highly adjustable, modular design that end-user feedback indicates is class-leading.

Putting the sensor in the right place meant that we wanted the bracket to be adjustable in all three axis. As a result, the sensor arm can be raised / lowered, the sensor holder extended or retracted along the horizontal arm, and the sensor holder itself rotated around the horizontal arm.

The sensor holder - which mounts to the horizontal bracket arm - was designed from the outset to be as flexible as possible - able to integrate all ultrasonic transducers currently on the market...regardless of manufacturer. In addition to the standard transducer slot at the front of the holder, we have also added a rear slot for a secondary sensor.

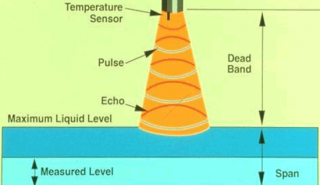

The second slot is particularly useful when a separate temperature sensor is used in conjunction with the ultrasonic transducer (think Siemens Milltronics XRS transducer with TS-2 temperature sensor). While the standard sensor holder is designed to accommodate up to a 1" NPT transducer, optional sensor holders are available to accommodate larger diameter transducers.

In addition, the sides of the sensor holder have been sculpted to allow large transducers (Magnetrol Echotel) to be mounted.

For applications where the installation space is confined, the modular nature of OCF's bracket allows us to swap out both the horizontal and vertical arms to fit the application. Need to mount a "zero deadband" sensor like Teledyne ISCO's Signature meter? No problem, just use a shorter vertical arm. Need to put a sensor away from an obstruction near the wall? Just use a longer vertical arm.

Adjustment of the bracket is also easy. Each arm or joint can be adjusted by a single hex wrench (provided with each bracket). While the sensor holder is secured to the horizontal arm by 1/4" nuts.

For very wide span applications, OCF's ultrasonic brackets can be provided with two vertical arms - so that one can be mounted on each side of the channel. Unlike fixed uni-strut designs, OCF wide channel brackets can be detached on one side - allowing the sensor to be rotated over to the other side to allow for maintenance / replacement / or calibration of the transducer.

In addition to the standard horizontal base mounting that other manufacturers' brackets employ, OCF brackets can be provided in vertical mount configurations. These configurations can be fixed position or adjustable as your needs dictate.

The modular nature of OCF's ultrasonic mounting brackets is such they they can be used in almost any application where an ultrasonic transducer needs to be mounted. Remember, if we put this much thought into a part as small as this, how much more did we put into the products themselves.