This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Using Ultrasonic Flow Meters with Flumes

The ultrasonic flow meter is one of the instrumentation workhorses for measuring open channel flows in general, and flumes in specific. Ultrasonic flow meters are generally low cost, robust, and provide a reasonable level of accuracy (+/- 0.02’ for a head change of less than 1.0’).

How Ultrasonic Flow Meters Operate

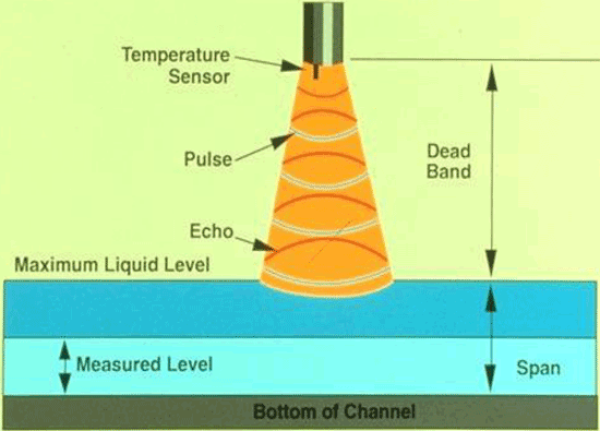

Ultrasonic sensors generate pulses of sound from the face of the sensor. They then measure the time for an echo to return – compensating for the variations of the speed of sound with temperature. The frequency with which pulses are generated varies by application and flow meter manufacturer [40 kHz (ISCO 4210), 50 kHz (ISCO Signature and Hach/Sigma 950), 75 kHz (Hach sc200), 125 kHz (Pulsar dB3)].

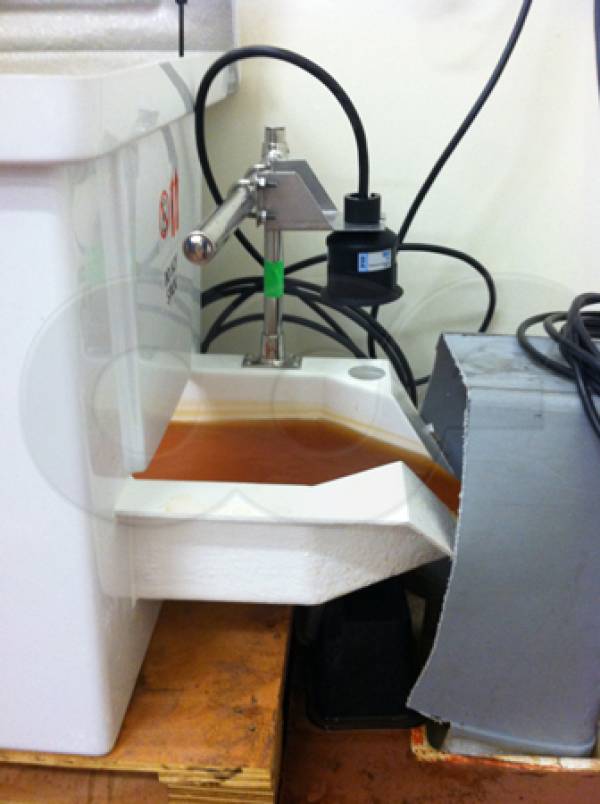

The ultrasonic sensor is suspended above the flow stream that they are measuring - it is not immersed or otherwise touch the flow stream. Being non-contact they are unaffected by chemicals, grease, suspended solids, or silt in the flow stream. Further, they do not require scheduled maintenance to clean them.

Mounting Bracket Styles

Currently there are four styles of ultrasonic sensor mounting brackets on the market that are used with flumes:

- Fixed position

- Fixed position (center mounted)

- Vertically adjustable (center mounted)

- Two position adjustable

Fixed Position

Brackets that are fixed height / length are formed by rigidly welding two pieces of stainless steel tube together. The bracket is secured at the top / side of the flume (either on the top flange or the concrete surrounding the flume).

There are no adjustments that can be made to the sensor height. Depending upon the sensor holder design, the sensor may be able to be slid down the horizontal arm of the bracket by some small amount. These brackets are not field adjustable.

Problems with the fixed design include the likelihood that the sensor will be mounted too close to the flume sidewall and the lack of adjustment to accommodate different sensor beam angles or deadbands.

Fixed Position (Center Mounted)

The fixed position (center mounted) bracket commonly supplied by contractors and ultrasonic flow meter manufacturers places the sensor on a strut frame work which is attached to either side of the flume so that the sensor straddles the flume and is located down the centerline.

This approach, while ensuring the sensor doesn't accidentally shift out of position is the least functional in terms of mounting flexibility and sensor maintenance. To access the sensor, the entire horizontal strut must be unbolted and the dismounted strut swung out of place [much like the vertically adjustable (center mounted) bracket below]. Beyond the initial fabrication, there is no easy adjustment of the sensor height to accomodate actual field conditions.

Vertically Adjustable (Center Mounted)

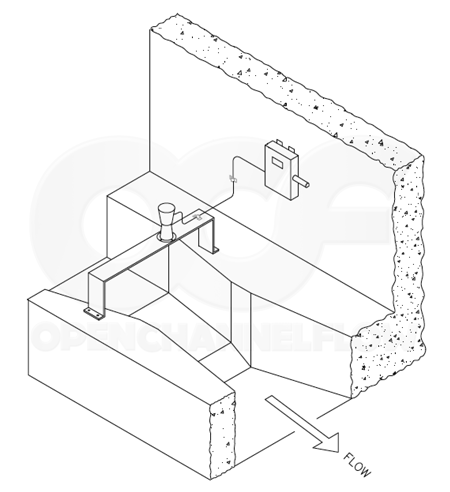

The vertically adjustable (center mounted) bracket utilized by Plasti-Fab (and copied by Virtual Polymer Compounds) attempts to solve the problems of the fixed bracket by mounting the bracket on a section of angle over the flume. The bracket is positioned down the centerline of the flume to avoid any potential turbulence occurring along the sidewalls of the flume.

Vertical adjustment of the ultrasonic sensor is made possible by sliding the sensor holder up / down the mounting bracket pole. Very limited horizontal adjustment can be made by rotating the sensor holder around the vertical mounting bracket pole.

On all but the smallest flumes, the support angle the bracket is mounted to must be unbolted and removed to access the sensor making the bracket cumbersome if the sensor must be serviced or a calibration target must be used to calibrate the flow meter.

Two Position Adjustable

Two position adjustable ultrasonic mounting brackets are designed to allow a maximum of flexibility in mounting ultrasonic sensors. The bracket consists to two independent horizontal / vertical arms connected by a pass-through union.

The pass-through design means that one arm passes through the union, which is in turn secured to the other arm. Traditionally, this means that the horizontal arm is allowed to slide up / down the vertical arm (although the bracket could be configured the other way around). On the long horizontal arm (50-100% longer than fixed bracket designs), the sensor holder is designed to slide in / out.

The resulting ability to place the ultrasonic sensor wherever it is desired, means that the two position adjustable design can accommodate all manner of sensor deadband / beam angle issues as well as positioning the sensor to avoid obstacles.

Both the horizontal and vertical arms can be replaced or modified – with longer or shorter ones added as needed.

In larger applications - or those where the sensor is to be mounted at the centerline of the flume - two vertical arms may be used, spanned by a long horizontal arm. When the sensor needs to be serviced / calibrated, one vertical arm can be disconnected and the sensor swung to the side of the flume. Note that when using the bracket in this manner, it is important to make sure that the ultrasonic sensor’s cable is long enough to allow the movement.

Flume Specific Issues

H / HL Type flumes – The angle of convergence of H / HL Type flumes is much greater than of other flumes (33.69º for H Type flumes vs. ~11.3º for Parshall flumes). As a result, a longer horizontal arm is to avoid measuring too close to the sidewall of the flume. The horizontal arm does not need to span the full flume width – it need only be long enough to position the sensor away from the sidewall of the flume.

Trapezoidal flumes - Larger Trapezoidal flumes can be quite wide. The sloping sidewalls of the flume can represent a significant portion of the flume’s width. For these applications mounting brackets with longer horizontal arms / arms spanning the full flume width should be used so that the sensor can be centerline mounted – ensuring that the flow meter does not detect the sidewall of the flume as the primary echo.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID