What is a Weir Box?

A Weir Box is simply a fabricated box or vault which incorporates a weir plate to measure the flow of piped water. Weir boxes work best when measuring flows from about 10 gpm to 500 gpm. Lower than that and accuracy falls off rapidly. Higher than that and the weir box becomes quite larger without aggressive flow conditioning.

Where to Use a Weir Box

Weir boxes really shine where:

Weir boxes really shine where:

- Solids need to be captured (dam seepage is an example)

- Where upstream conditions preclude the use of a flume or other primary device

- Where piping conditions are unusual - multiple pipes coming in and/or where pipes rise up or fall into the box entrance or where pipes need to leave vertically

- Where the flow stream needs to be separated or controlled

- Where high levels of flow conditioning are necessary - short approach runs, high turbulence, high velocities

Weir Plate Types and Angles

Weir boxes can incorporate V-notch, Cipoletti, or even rectangular weir plates – although the latter are uncommon due to the width of the box required.

V-notch weirs are usually the 22-1/2º, 45º, and 90º sizes. Cipoletti weirs are usually 12” or 18” W.

Flow Conditioning in a Weir Box

After the flow enters the weir box – and before it reaches the weir plate – the flow usually goes through a baffle (or set of baffles) to slow / condition the flow.

After the flow enters the weir box – and before it reaches the weir plate – the flow usually goes through a baffle (or set of baffles) to slow / condition the flow.

These baffles can be over/under flow style or flow through perforated plates.

Over/underflow baffle plates are commonly used when the flow into the weir box is coming in horizontally. Perforated baffles are used when the flow enters vertically into the box.

Measuring in a Weir Box

Unlike flumes where the flow level is measured in the flume, when measuring weir flow the point of measurement is upstream of the plate, at least 3-5 Hmax (Hmax being the maximum anticipated head).

Also, the zero elevation (elevation from which the water level is measured to determine the flow rate) is above the weir box floor – at least 2 Hmax.

It is this elevation above the channel flow that can cause trouble for an operator if the elevation is not marked on the box or recorded elsewhere.

Weir Boxes and Low Flows

While weir boxes (using V-notch weirs) can measure low flows, keep in mind that they are not accurate below 3.99 GPM - and then only when using a 22-1/2º V-notch weir.

For low flows a HS flume is a better choice as they can, depending upon the size of HS flume, measure much lower flows - down to 0.0718 GPM (or 2% of the 22-1/2º V-notch weird minimum flow rate).

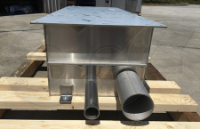

Weir Box Materials

While weir boxes can be made of really any material - so long as it is watertight - they are usually made from:

- Aluminum - lightweight and corrosion resistant

- Fiberglass - lightweight, easily customized, and corrosion resistant

- Galvanized steel - lowest cost

- Stainless steel - greatest resistance to corrosion