This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Benefits of Packaged Metering Manholes to Consulting Engineers

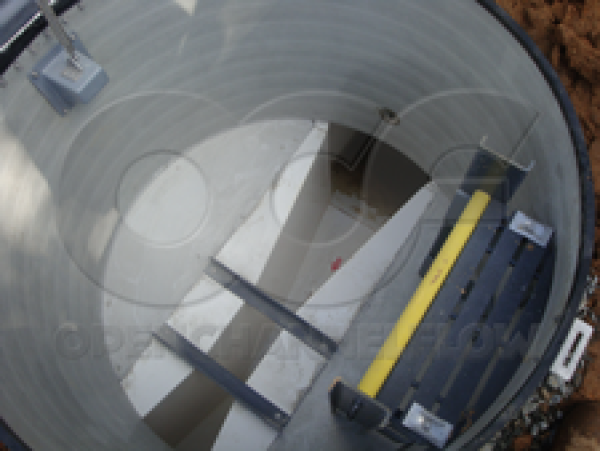

Fiberglass Packaged Metering Manholes are a great solution to the problem of measuring piped flows below grade and provide a unique set of benefits to consulting engineers who specify them.

Accuracy, in this context means, installation accuracy by the contractor and the flow measurement accuracy of the completed structure.

Properly installing a flume can be a challenge to a contractor. The job of installing the flume is usually given to a subcontractor who may or may not be familiar with the particular needs of a flume’s installation. From setting the flume to forming suitable transitions into and out of the flume – there are many steps in the process where problems can arise. Done wrong and the result is an ongoing headache for the engineer and their end user.

Factory integration of the primary device eliminates these potential problems and also ensures single-source responsibility (no finger pointing between subcontractors). Consulting engineers can rest easy knowing that the all the contractor needs to do is to provide a level concrete slab for the manhole to mount to.

Arriving on site as a single, integrated unit, a packaged metering manhole is ready for immediate installation and use. Engineered transitions into and out of the flume mean that, properly applied, the installation will provide accurate flow measurements.

Longevity

With tens of thousands of standard and flow monitoring installations throughout North America, fiberglass manholes have demonstrated extremely long service lives. Installations going as far back as the 1960’s are still going strong – almost 50 years since they were originally installed!

Now not all applications will required this same level of longevity, but for certain applications (landfills in particular), this is of critical importance.

Reduced Inflow

The unique construction of fiberglass packaged metering manholes make the units watertight and not subject to inflow in the same way that concrete manholes are. The monolithic nature of the manhole means that there are no seams to leak and the available watertight tops mean that water can’t enter through the top of the manhole.

The unique construction of fiberglass packaged metering manholes make the units watertight and not subject to inflow in the same way that concrete manholes are. The monolithic nature of the manhole means that there are no seams to leak and the available watertight tops mean that water can’t enter through the top of the manhole.

While a certain amount of I&I is inevitable in a collection system, packaged metering manholes are not contributing factors to it.

Environment

As a single-piece, monolithic structure, packaged metering manholes are watertight and not subject to the corrosion and eventual leaks that concrete manholes are subject to.

This can be of particular importance when monitoring manholes need to be place near creeks or streams or where ground water is high. An unintentional leak due to corrosion into these bodies of water can contaminate drinking water supplies and damage aquatic life.

By isolating the wastewater being metered, packaged metering manholes serve as a long-term means of protecting the environment.

Economics

In today’s tight economy, budgets are certainly constrained. Consulting engineers must, therefore, make sure that they maximize their client’s funds for not only the present, but also the future.

Historically, the upfront costs were the determining factor in deciding whether or not to use a packaged metering manhole. Based upon that criterion, packaged metering manholes typically were only selected when the flume was large enough to not economically fit into a concrete vault.

Recently, though, there has been a developing emphasis on life-cycle costs.

Over time, the cost of concrete manholes increases. This is because of the need for regular inspection, maintenance, and rehabilitation to keep a concrete manhole in good repair.

Over time, the cost of concrete manholes increases. This is because of the need for regular inspection, maintenance, and rehabilitation to keep a concrete manhole in good repair.

The cost of fiberglass manholes, on the other hand, decreases over time. The manholes do not corrode; there is no need for rehabilitation or maintenance; and no infiltration.

Additionally, considerably less equipment and manpower is required to install a packaged metering manhole. Weighing ~10th that of a traditional concrete structure, there is no need for large cranes to move or place the units, very little line down time (reducing bypass costs), and fewer personnel required to complete the installation.

Client Satisfaction

The hallmark of a good consulting engineer is one who exceeds his client’s expectations in terms of both system design and functionality. Fiberglass packaged metering manholes can go a long way to providing that level of service. The units provide a superior working environment for operators and are highly customizable to each particular client’s or site’s needs – maximizing the usability of the installation.

Overwhelmingly, customers who have used fiberglass packaged metering manholes prefer them over traditional concrete structures and specify their use on future projects.

Images: The University of New South Wales Ordour Laboratory, Winterport Water District

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID