This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Choosing Between a Bubbler and an Ultrasonic Flow Meters for Flumes and Weirs

After you’ve selected whether flume or weir for your application, you then have to think about which type of flow meter to use. Usually this comes to down to using an ultrasonic or a bubbler flow meter.

Ultrasonic Flow Meter Advantages

Price is a strong advantage for ultrasonic meters – in many ways ultrasonic meters are “good enough”. There are numerous manufacturers in the marketplace and the technology is well tested and decades old.

Ultrasonic meters are available in line powered, solar powered, and battery powered models allowing for installation flexibility.

With no moving parts, there is nothing to maintain, failure rates are low, and the mean time between failures (MTBF) is long.

Ultrasonic Flow Meter Disadvantages

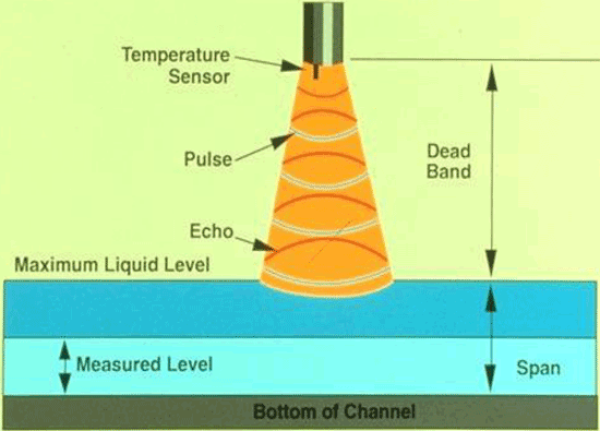

The accuracy of ultrasonic flow meters can be affected by a number of factors, including:

- Foam

- Turbulence

- Steam

- Large water / air temperature differences

- Floating debris / oil / grease

- Wind

Also, over the depths usually experienced in flume and weir installations, the level measurement error of an ultrasonic flow meter is +/- 0.02-feet [1/4-inch] compared to bubbler meter measurement error of +/- 0.005-feet [1/16-inch]. For small flows, this can be a significant error.

The physics of the beam angle and dead band of ultrasonic transducers is such that unless the transducer is properly mounted and false echo cancellation is good, an ultrasonic meter may sense the sidewalls of the flume or weir before it senses the water surface.

Finally, while bubbler meters are self-calibrating, ultrasonic meters require periodic calibration or they will tend to drift over time.

Bubbler Flow Meter Advantages

The primary advantage of bubbler meters is their accuracy – typically 4 times finer measurement resolution than ultrasonic meters [1/16-inch vs 1/4-inch]. For low flows, this is particularly important.

Bubbler meters also are unaffected by foam, steam, turbulence, wind, floating debris, and liquid temperature fluctuations.

Also, bubbler meters self-calibrate, with long-term level calibration change of only 0.5% of readings per year.

Bubbler Flow Meter Disadvantages

Bubbler flow meters suffer from one very large drawback: they have a moving part – the air compressor. The compressor is a weak point for two reasons: it is a wear item that will ultimately require maintenance and it is (relatively) energy intensive.

The mean time between failures (MTBF) for bubbler flow meters is higher (due to the compressor) than those for ultrasonic meters. While meter manufacturers don’t provide statistics, field observations are that bubbler meters will require maintenance years earlier than ultrasonic meters in similar applications. This isn’t to say that bubbler meters have short lifespans, simply that they will require maintenance / replacement much sooner than an ultrasonic would.

The need to run the compressor to provide air for the meter means that most bubbler applications require a permanent power supply – or a large number of solar cells. For remote installations, running power out to the site isn’t always possible or practical.

When suspended oil and grease are in the flow stream, the bubbler tube opening can clog over time. This also can happen in applications where biofouling is present or where marine organisms are growing – although this can be mitigated by using copper bubbler tubes.

Finally, the cost of bubbler flow meters is always higher than that of ultrasonic meters. Moving parts and complexity are the culprits here. Likewise, maintenance costs are also higher.

Images: Hach, Teledyne ISCO

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID