This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

A Contractorâs Guide to Buying Flumes

Being a contractor isn’t easy. There are weather delays, subcontractors to schedule, equipment to install, progress charts to update, client meetings, and permits to obtain. The list goes on and on.

You can't be an expert in everything and even many consultants don’t design flumes or do flow monitoring on a regular basis.

What you need in a flume manufacturer is:

- Someone who understands flumes and open channel flow

- Someone who produces a well-built, trouble-free product

- And someone who stands behind their products if you do run into trouble

In evaluating among flume manufacturers and their offerings there are a number of things to consider.

Construction

To the untrained eye one flume may look very much like another – at least at first.

Flume manufacturers have a number ways of tailoring their products to hit a specific price points or profit margins – not all of which are apparent by just looking at a flume.

When evaluating a flume’s construction remember to look at:

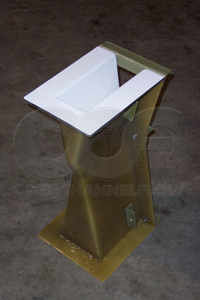

Gel Coat

All surfaces on a flume should be thoroughly gel coated – both inside and outside. Flumes frequently are stored on site for some period of time (usually upside down to protect the flow surfaces). When a flume lacks exterior gel coat, the fiberglass laminate suffers from U.V. exposure, which begins to weaken the flume. Additionally, flumes in surface water applications are frequently installed where only a portion of the flume in buried or encapsulated. Again, those portions of the flume that are not protected by either gel coat or burial begin the process of U.V. deterioration.

Simply painting the outside of the flume with resin is not gel coating it. The formulations for fiberglass resins and gel coats are quite different as are their intended purposes. Gel coat also acts as a corrosion barrier for the laminate – a consideration when monitoring acidic mine discharge (AMD) or landfill leachate.

Gel coats should be cured to 15 mils thick and must contain U.V. inhibitors.

All flow surfaces should have a smooth white gel coat finish. White is used to aid in the visual determination of level and helps to show up surface defects. When darker colors are used it is more difficult to visually determine the level in a flume and see inclusions or other fabrication errors.

To gain a specifiable advantage, some manufacturers say that gel coat should be 25+ mils thick. When applied to thickly gel coats become brittle as they lack the reinforcing strength of the chopped glass in the actual laminate. Also, is applied thicker when it is applied – shrinking as it cures. So while 25+ mils may be applied wet, it is almost never that thick when cured.

Gel coat is a good indicator of overall quality. Doing it right take time.

Remember, if the flume manufacturer is cutting corners here - where you can see it - where else are they cutting corners?

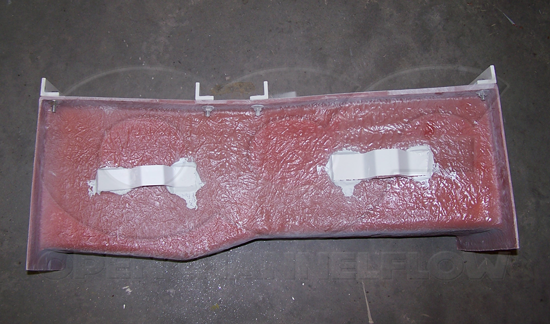

Laminate

For small and medium sized flumes the laminate thickness should be 1/4-inch [0.635 cm]. Thinner laminates, while potentially strong, are flexible and can distort during installation. Larger flumes should have thicknesses at least 3/8-inch [0.9525 cm]. Thicknesses are excluding exterior ribbing and embedded reinforcements.

Additionally, the laminate should be consistent in thickness along the part. While there will be some thickening in corners, other areas of the flume should be consistent in thickness. A lack of consistency will weaken the part and is indicative of a lack of control during the production process.

Cost

Aquisiion cost is important for a flume, but it is not the whole story. While you certainly don't want to pay anymore than you have to, you also need to make sure that you are receiving quality and support with your order.

Remember that at some point low price is just cheap!

Expertise

One way to quickly judge a manufacturer’s expertise in flow measurement is to look at their web site. For many, a company’s web site is their primary marketing tool.

With that in mind consider:

- Does the site look professional or is it essentially just a couple of brochures scanned or duplicated.

- Is there any depth to the information?

- If the content is no more than a page or two deep, the question would be why?

Focus

This may sound basic, but to many manufacturers flumes are just something else to make – right along with their boats, car parts, feed troughs, toll booths…

A flume manufacturer should focus on flow and flow alone. Dividing time and energy between disparate products reduces the likelihood that a flume manufacturer has the flow expertise that you will need.

Submittals

Consider:

- How quickly are submittals turned around?

- This shouldn't be more than a week and usually should only be a day or two.

- Are submittals included in teh cost of the flume or is there an extra "fee"?

- Do the submittals look profession?

- Are the submittals tailored to each specific project or are they a collection of general information and brochures with items crossed out or circled and blank spaces filled in?

Confusion during the submittal phase can be costly later on. If the manufacturer can't take the time here to clearly identify what they are providing for you, odds are something will be missed during production.

Support

As work is becoming more distributed and mobile, the ability to get support through multiple channels is becoming more important.

- Multiple ways to get support

- Mobile, social media, knowledgebase, toll-free number, email – they all have their place

- Guides (preferably visual) on how to install the product

- Words are great, but pictures are better. Some time it is easier to grasp an idea by seeing how some else did something.

- How long are the installation instructions

- In general, the longer the better and the more likely that the flume manufacture has seen just about anything you are likely to run across in the field.

Submittals are something you don't usually get until after you've submitted your bid and have issued a purchase order. One way to do your homework upfront is to ask for a copy of a submittal the flume manufacturer recently did. That will give an an excellent idea as to how they perform. If they hem and haw here, keep walking.

Warranty

Here, longer is better. One year is barely adequate. Two years is passable. Five years is ideal.

Remember that your contractor's warrany for a job usually is one year from the date of substantial completion. That can easily be a year from when the flume orginally shipped. With a one year warranty the flume may no longer be warranted before you even get off the job! With two years it might be warranted for some period of your warranty, but possibly not all. At five years both you and your client are covered.

Image: University of Delaware / USDA / NSF - Fair Hill Watershed Study

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID