This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

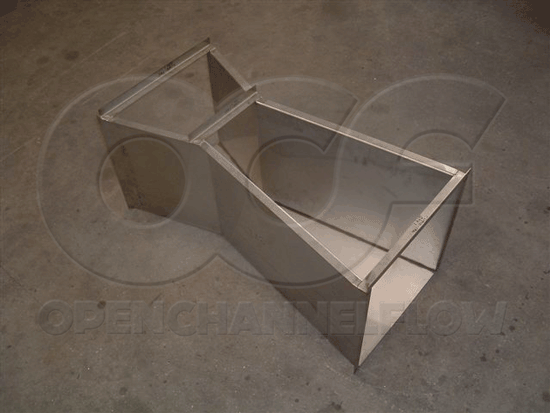

Cutthroat Flumes: See What's Missing

The Cutthroat Flume is one of the more recent styles of flumes to be developed. Development of what would become the Cutthroat Flume began during the 1960’s at the Utah State Water Research Laboratory. The goal was to create a low-cost flume to monitor surface water flows in relatively flat gradient channels.

Cutthroat Innovations

There are several innovations that set the Cutthroat Flume apart from other flume styles, including:

Deletion of the Throat Section

The inlet walls converge from the inlet to the throat and then immediately diverge. There is no extended throat as there are on other flumes. It was for this unique characteristic that the flume was given the name “Cutthroat”.

Flat Bottom

Many flume styles developed before the Cutthroat utilize a change in floor elevation to generate supercritical flow through the throat. The Parshall Flume has a drop in the throat and then a partial recovery in the discharge. The Palmer Bowlus and RBC flumes both have raised throat ramps. The flat bottom of the Cutthroat Flume was specifically chosen for the applications it was developed floor – flows in low / flat gradient channels.

The flat bottom has allowed the Cutthroat Flume to become the flume of choice for many retrofit applications. Unlike the Parshall Flume which requires either a change in the downstream channel (to be set flush with the floor of the upstream channel) or elevation of the flume itself (to allow for the drop and recovery of the floor in the throat and discharge section), the Cutthroat Flume can be manufactured to fit directly on the channel floor – with the flume sitting above the channel floor by no more than the thickness of the flume’s floor.

Standardized Sidewall Convergence / Divergence Ratios

All Cutthroat Flume inlet sidewalls contract at a 3:1 ratio. Likewise, all Cutthroat Flume outlet sidewalls diverge at a ratio of 6:1. The advantage here is that entire families of Cutthroat Flumes can be developed from a standard length by simply moving the sidewalls in or out as necessary - allowing intermediate sizes to be developed without the need for laboratory testing. This ability to develop a range of sizes without testing contrasts with Parshall Flume (where the flumes are similar in layout, they not identical) and is unique to the Cutthroat Flume.

Applications

Since their developement, Cutthroat Flumes have proven to be adaptable to a wide range of applications:

- Surface water

- Irrigation

- Industrial flows

- Sewage

- Proportional flow splitting

- Mine dewatering

In applying Cutthroat Flumes to the flow of sewage, a minimum throat size of 3-inches [7.62 cm] should be used to avoid the risk of solids clogging in the flume's throat.

One limit of the Cutthroat Flume is that for maximum accuracy, the height of flume's sidewalls should not exceed 40% of the flume's length. Above this, while flow can still be measured, the accuracy of the measurement decreases.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID