This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Directing Flow Into & Out of Flumes with Wing Walls

In selecting a flume, it is generally advisable to choose the smallest flume capable of handling the anticipated flow rate. However, this means that the even at its widest the flume is normally narrower than the channel is wide. The problem then becomes how to transition flow into and out of the flume.

In selecting a flume, it is generally advisable to choose the smallest flume capable of handling the anticipated flow rate. However, this means that the even at its widest the flume is normally narrower than the channel is wide. The problem then becomes how to transition flow into and out of the flume.

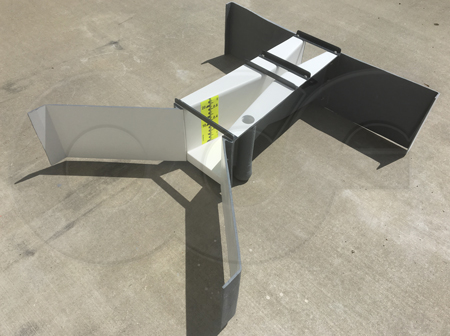

You don’t want the transition from the channel abrupt as this will cause turbulence and a poor velocity profile which will negatively impact the flume’s measurement accuracy. So what is needed is, on the inlet, a gradual transition from the channel banks to the flume’s inlet. Wing walls are the way to accomplish this. At their simplest, wing walls are no more than flat walls which direct flow into the flume our out of a flume.

Inlet Wing Walls

On the inlet, flat wing walls usually enter the flume at no more than a 45º angle. Above 45º - and even at 45º in some cases – and a wave / trough phenomenon can form where the wing walls join the flume. As the flow rate increases, this wave action moves down the flume, towards the throat section. Depending upon where the wave action is in the inlet / converging section of the flume, the result may the flume over or under indicating what the flow rate is.

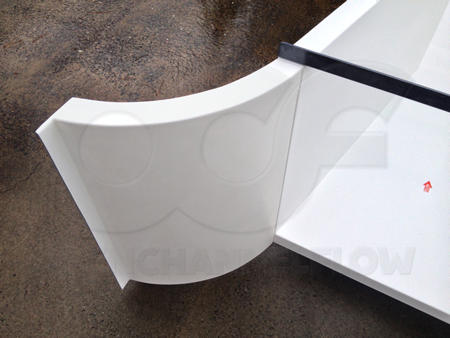

Where possible, it is recommended that inlet wing walls have a radius to them so that the flow is directed into to the flume parallel to the angle of the flume’s sidewalls. Radiused inlet wing walls also do not suffer from the wave / trough phenomenon that can affect 45º wing walls.

Depending upon the channel conditions, the inlet wing walls may also include a skirt so that flow does not undermine / bypass the flume.

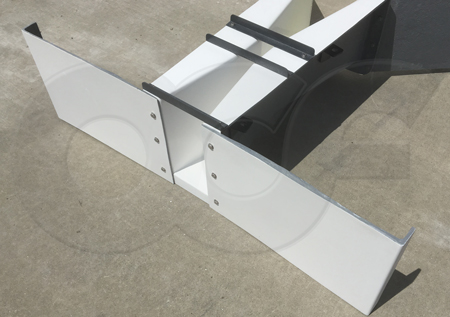

Outlet Wing Walls

On the outlet, wing walls serve the function of transitioning the flow back into the channel as it leaves the flume. Depending upon where the flume is installed, the wing walls can be perpendicular to the flow or can gradually expand outward.

In concrete or armored channel installations, perpendicular wing walls are suitable. In earthen channel installations, a more gradual transition is necessary to minimized downstream scour.

Wing Wall Material of Construction

What the wing walls are made of is not as critical as how they transition the flow into/out of the flume in the correct way (to minimized turbulence /undermining/scour, are water tight, and the material is compatible with the flow stream.

Concrete, corrugated sheet, erosion protected packed earth, timber, and fiberglass plate have all been used to make wing walls.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID