This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Freestanding Flume Installations

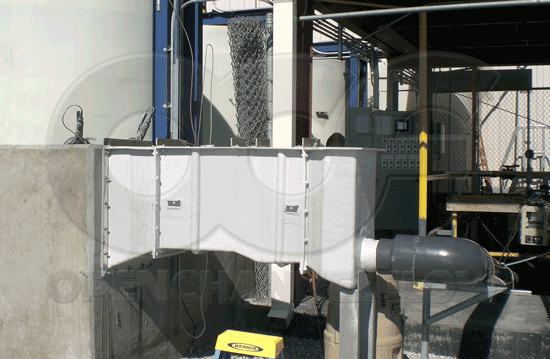

The common method of installing a flume is to encase it in concrete or an earthen channel. Sometimes, though, flow needs to be measured where this just isn’t an option.

For these installations something else is needed: a freestanding installation!

Freestanding installations can take many forms; from suspended flumes to elevated flumes. Regardless of their details, one thing remains the same: the flume must be not only strong, but also rigid.

Why rigid? Most flumes are empirical devices – their shapes have been carefully selected and researched to provide specific flow characteristics. Flumes that deviate from nominal dimensions discharge differently and usually in a way that is not readily correctable. For a freestanding installation, the support provided for a flume’s sidewalls is no longer present. The walls must be sufficiently rigid to keep the flume in dimension under flow conditions.

Light weight bracing, narrow ribs, (or in some cases no) anchoring clips, and thin laminate (less than 1/4-inch [0.635 cm]) all can lead to a flume distorting in a free-standing installation. To combat this a combination of stout dimensional bracing at the top of the flume, wide exterior stiffening ribs along the sidewalls / across the bottom of the flume, multiple anchoring clips, and increased laminate thickness all can be used to keep a flume in dimension.

Freestanding installations typical utilize smaller flumes (throat widths less than 12-inches [30.48 cm]), although certain flumes larger than this are sometimes uses - commonly H and HL flumes. Above 12-inches [30.48 cm], it is unusual to see Parshall, Montana, or Cutthroat flumes used in freestanding applications.

Remember that in freestanding installations that it is important that the bottom of the flume be supported. The flanges and end connections provided with most flumes are not intended to take the full weight of the flume under flow conditions. To avoid a potential failure of the installation, supports perpendicular to the direction of flow should be used.

All Openchannelflow flumes designed and manufactured to be capable of containing their anticipated flow depth without visible distortion.

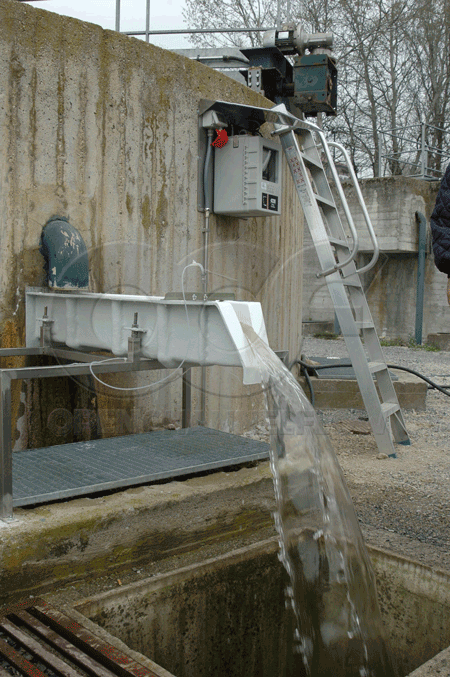

As part of our continuous quality program, flumes are randomly pulled from production and static fill tests conducted. Here the ends of the flume are capped and sealed to make them watertight. The flume is then filled with water to its maximum rated depth and allowed to sit (soak). Careful measurements are made of the flumes interior dimensions before and after fill and soak.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID