This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Openchannelflow | Parshall Flume Manufacturer

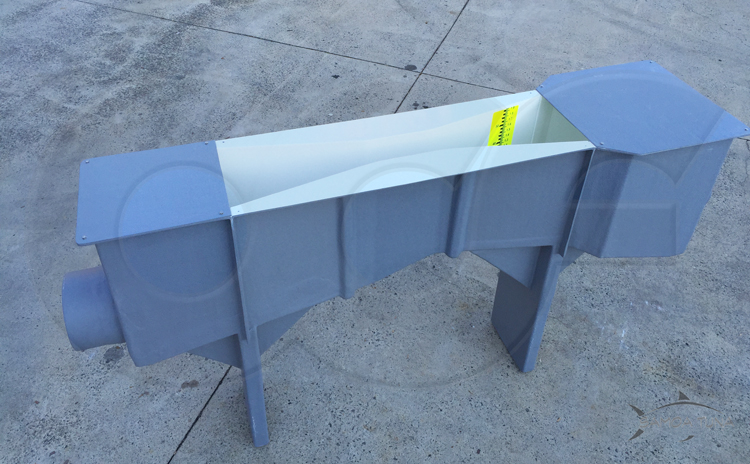

In our blogs, we frequently highlight our abilities as a manufacturer of primary devices, including Parshall flumes, for the devices for the measurement, conditioning, and control of water in open channels. But what does it mean to be a manufacturer?

Being a Parshall Flume Manufacturer

What does it mean to be a Parshall Flume manufacturer? Simply put, it means that we actually make the products that we sell.

Now this would seem to be obvious, but when you survey the market for open channel flow primary devices in general, and Parshall flumes in particular, that isn’t always the case. There are a number of companies sell Parshall flumes – some even touting their 25+ years in the industry – that are nothing more than resellers.

As a reseller, these companies may be buying another company’s branded flumes or they may contract to have “their” flumes made. Either way they simply don’t control the product, in a number of critical areas:

- Raw materials

- Methods of production

- Dimensional tolerances

- And, ultimately, the finish quality

Resellers/ outsourcers may perform a cursory “quality control” inspection once the product is done, but our experience is that this sort of inspection can only address gross product defects, it does nothing to help create a high quality, long lived product. Further, when these companies use a “network” of outside companies, the problems compound.

Continual Innovation

Openchannelflow has a laser focus on what we expect of ourselves. We don’t focus on where our competitors are, but where WE want to be. This, in turn, drives a constant evaluation of our products, how they are produced, and how they are used. The product that we make today, is not the product that we made year ago.

This innovation is only possible by closely integrating Openchannelflow’s sales, engineering, and manufacturing operations. Each day, as an organization, we review our current production schedule, our work-in-progress, and future product ideas (large and small). These daily interactions, both scheduled and informal, help us to bring exceptional value to our customers by allowing us to continue refine our operations and products.

Application Knowledge Driving Product Development

Integration of our sales / engineering / manufacturing operations allows us to drive institutional knowledge throughout the company. A good example of this is the introduction of spirit levels in each flume that Openchannelflow sells.

Our support services noticed a trend in customers asking post installation questions regarding the need to have the converging section floor in Parshall flumes level - and the impact on accuracy that a non-level installation could have. Sales immediately put together an article on the correcting for settlement in Parshall flumes – which supported our existing flume customers, while at the same time an engineering solution was sought to reduce the likelihood of a out of level installation. At the same time, engineering developed a solution and downselected possible vendors. Within a day of manufacturing receiving vendor samples, a preliminary solutions was introduced into the manufacturing process.

This speed of response and integration into the product offering simply can’t exist if manufacturing isn’t integrated with sales.

Customization

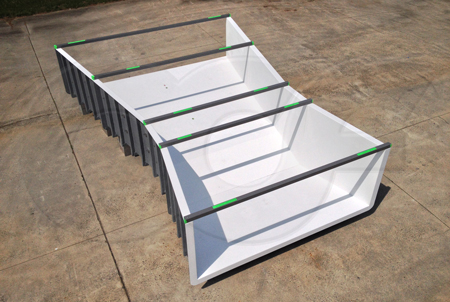

Close interaction between engineering and manufacturing allows Openchannelflow to bring custom solutions that solve our customers' problems quicker to market. In additon, the interplay between the departments means that the solutions are well though out and expertly implemented.

Why Do Companies Choose to Be Resellers?

Ultimately, the choice to own produciton facilities comes down to Cost and Control.

It's cheaper to simply contract or job-shop produciton out to another company. Contract manufacutrers can make any number of parts for different industries. Ones that we have seen include: after-market car parts, lift buckets, video game cabinets, and water slides. By making parts for a range of customers, the overhead costs applied to a a resellers products are lower, meaning that they can either sell the product for less or make more profit....neither of which help the customer. The problem of such a difussed focus is that specialization and craftmanship simply don't develop. Why would they? There is little understanding of the product or how it brings value to the end user.

As for control, if an organization isn't focused on generating customer value, then control of the materials, methods, and, ultimately, quality, become secondary and the decision to outsource / contract / job-shop becomes easy. Again, the goal of many resellers is purely profit, not pride in their products, not craftmanship, and not value for their customers. Regardless of what lipservice they give to "Service" and "Value", cost is their selling point, and while there are always customer how look at that alone, Value is what a true, integrated manufacturer looks to bring to its customers.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID