This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

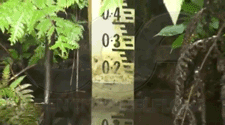

Staff Gauge Measurement Errors in Flumes and Weirs

There are several components to measurement errors when using Staff (Level) Gauges to determine flow depth in a flume or weir.

There are several components to measurement errors when using Staff (Level) Gauges to determine flow depth in a flume or weir.

In general, staff gauge reading errors can be attributed to:

- Distance between the staff gauge and the observer

- The angle at which the gauge must be read

- Turbulence of the water surface

- The graduations of the staff gauge

- Cleanliness of the gauge

Distance

The distance from the staff gauge and the observer can be critical. Undersized fonts quickly become undistinguishable at even relatively short distances.

| Numerial Height | Viewing Distance |

| 5/16" | 7' |

| 1/2" | 12' |

| 3/4" | 18' |

| 1" | 25' |

| 1 1/2" | 36' |

| 2" | 49' |

| 3" | 74' |

| 4" | 113' |

| 6" | 150' |

| 9" | 300' |

The viewing distance heights above are maximum distance based upon based upon the numeral height under calm conditions. In applications where the flume or weir will experience surface turbulence, larger numeral sizes should be used. Openchannelflow gauge heights begin at 3/4” and can be increased as necessary. The 3/4” size is sufficient for Parshall flumes up to 12-feet in size (as the flume is ~ 14’-8” wide at the primary point of measurement).

Gauge readability can be enhanced by contrasting the coloration of the numerals / increments and the background. Openchanneflow has standardized on black numerals on a high visibility yellow/green background.

Gauge Angle

As we have seen above, the gauge to observer distance can impact readability. Likewise the angle of the observer to the gauge can also impact gauge readability. For applications where the observer is much higher than the gauge level, it can be difficult to accurate distinguish the indicated level, particularly in the presence of surface turbulence.

While not as desirable as a surface level observation when the flume or weir is below grade, it may be more practical to have the operator read the staff gauge when standing at the level of the device. In deep applications where this is not possible (potentially due to confined space considerations), visual staff gauge observations may need to be foregone.

Surface Turbulence

To obtain the most accurate level measurement when monitoring turbulent flows, the staff gauge should be installed inside of a stilling well. Stilling wells act to dampen and smooth water level elevations while still allowing the level in the stilling well to reflect the level in the flume or weir in real time (assuming the stilling well has been sized so as to not experience stilling well lag).

Staff Gauge Gradations

Under ideal flow conditions, staff gauges can generally be read to within the about 1/8”, when the observer is close to the gauge. Gradations finer than this do not add to the overall legibility of the gauge and can in fact make it more difficult for an operator to correctly discern the level on the gauge.

As turbulence, distance from the observer to the gauge, and angle to the gauge increase, readability may be limited to no more than 1/4” (or more).

Gauge Cleanliness

A staff gauge that accumulates dirt, debris, or biological growth on it will hinder readings, which can result in substantial measurement error. Staff gauges should, therefore, be located where they are accessible and can be readily maintained.

Sources: Distance Legibility Chart, APCO, Clemmens, A., Walh, T., M. Bos, Replogle, J., Water Measurement with Flumes and Weirs, Publication 58, International Institute for Land Reclamation and Improvement, 2001

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID