This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Staff-Level Gauges for Water Level Measurement

Staff ("Head" or "Level") Gauges provide a quick, visual indication of the level of water in a channel, flume, or weir. Although they should not be solely relied on when more precise level measurement devices are available, staff gauges allow operators to quickly gauge the relative level of water and then proceed with other duties.

Water rarely flows in a nice, tranquil manner. Usually, even in well conditioned flows, there is some amount of surface ripple or turbulence present.

Unless otherwise indicated, the assumption is that the graduations on a staff gauge are in feet, 1/10-feet, and 1/100-feet increments. Some gauges may be in a dual scale format (i.e. some combination of Imperial depth, SI depth, and flow units). Higher end gauges will provide an indication at the top of the scale and/or along the side of the scale as to the units of measurement. Rulers or other devices repurposed as staff gauges typically do not have this user-friendly characteristic.

Locating a Staff-Head Gauge

Where possible, staff gauges should be located in a part of a steam or channel where the water is relatively free of turbulence. In natural channels and streams this may be difficult as other factors may affect where the gauge is put (most notably site access).

For flumes and weirs, the location of the gauge may either help or hinder the calibration of a flow meter. Gauges should be placed where they can be quickly read and compared against the flow meter's reading. More than one otherwise good installation has been compromised by poor flow meter / staff gauge placement. Thought should be given when planning an installation as the method (and personnel) required for meter calibration.

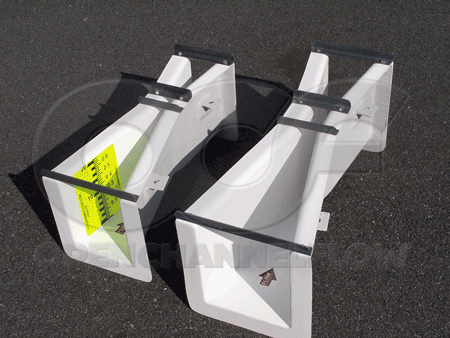

Gauges in Flumes

In flumes, the point of measurement is dictated by the flume type and size and here the location selection is usually only left / right in the flume. However, if a stilling well exists (or can be added) a staff gauge could be located there also. Stilling wells may be particularly useful if foam or surface turbulence is present in the main body of the flume.

When reading a staff gauge at a new site, thought shoudl be given as to whether the gauge is a direct read or not. Direct read gauges correct for sidewall geometry, while indirect read gauges require some adjustment be applied to the gauge reading. Stafff gauges in flumes with vertical walls (Parshall, HS / H / HL, Cutthroat, and Montana) are all direct read. For Trapezoidal and RBC flumes, the gauges may or may not be direct read as the sidewalls are not vertical.

In flumes, the point of measurement is dictated by the flume type and size and here the location selection is usually only left / right in the flume. However, if a stilling well exists (or can be added) a staff gauge could be located there also. Stilling wells may be particularly useful if foam or surface turbulence is present in the main body of the flume.

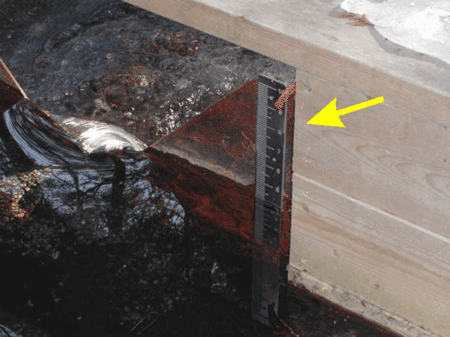

Weirs with Gauges

In weirs it is not uncommon to see a staff gauge mounted on the weir face itself. Etched on, screwed to, or otherwise located on the weir plate, staff gauges in these instances are intended only for general level measurements. They are not – and should not be assumed to be – entirely accurate. The reason for this is that the surface of the water draws down as it approaches the weir crest. In a normal application, the staff gauge should be located upstream of the weir at least 3-4 times the maximum anticipated head, Hmax, due to this drawdown effect.

Gauge Maintenance

Biological growth, vegetative mater, scum, scale, and other debris can all collect / grow on the indicating face of a staff gauge. Best practice is to clean and inspect a staff gauge every time a site in visited – whether the gauge is used during the visit or not.

Waiting to inspect and clean the gauge may make it harder in the long run to remove any accumulation on the gauge. Marine organisms in particular can be difficult to remove once they become established.

Materials of Construction

Porcelain enameled iron has been the standard material for staff gauges for years. Enamel is hard, smooth, and resistant to biological growth. Unfortuantely, once the enamel is cracked, the iron core of the gauge begins the oxidation (rusting) process. Also, the method of manufacturing means that most porcelain enameled gauges are manufactured in fixed lengths - most of which do not correspond to the depths of standard flumes.

Over the past decade new high strength, U.V. resistant materials and methods of construction have been applied to staff gauges, including:

- Fiberglass encapsulation

- Stainless steel

- PVC

- Aluminum / die-bond backed

- Lexan or Polycarbonte coated Mylar

Digital imaging and new substrates now allow much greater flexibility in terms of format and colors than ever before. In open channel applications there is a trend away from the standard black on white gauges of the past to higher visibility black on yellow (or better yet black on high visibility yellow-green).

Images: Maine Geological Survey, National Institute of Water and Atmospheric Research (NIWA), Ministry of Environment, Lands and Parks Resources Inventory Branch, British Columbia

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID