This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Using an Ultrasonic Flow Meter with a Flume

The combination of a flume with an ultrasonic flow meter is a very reliable method of measuring wastewater flows. The set-up can be low cost and provide good overall accuracy.

System Components

Flume

A specially shaped, fixed hydraulic device that accelerates subcritical, open channel flow in such a manner that the flow rate in the upstream section of the flume can be determined by a single level measurement.

Ultrasonic Flow Meter

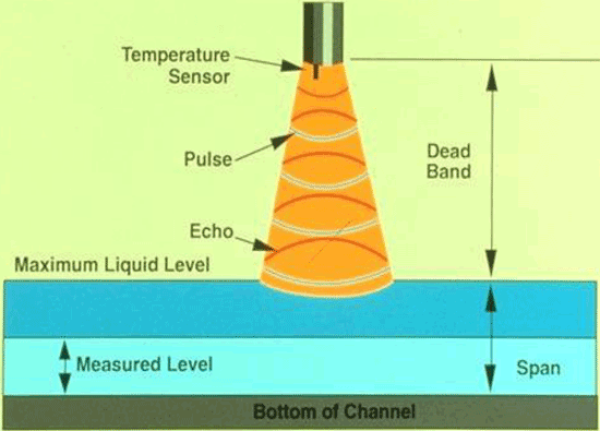

A sensor mounted above the flow stream transmits a sound pulse that is reflected by the surface of the water. The elapsed time between sending a pulse and receiving an echo determines the water level in the flume. This level measurement is then converted into a flow rate in the meter through the use of a preprogrammed equation specific to the type and size of flume being used.

System Accuracy

The overall system accuracy of a flume / flow meter installation is typically +/- 8-10%. The components that go into determining the overall system accuracy are:

- Flume accuracy

- Flow meter accuracy

- Installation error

- Flow meter calibration error

- Approach conditions

Advantages

An ultrasonic sensor is easy to install and, because it does not contact the liquid, requires minimal maintenance and is not affected by grease, suspended solids, silt, and corrosive chemicals in the flow stream. Additionally, it is not affected by fluctuations in the temperature of the flow stream.

Ultrasonic meters are relatively low cost and require little in the way of maintenance. With no moving parts, meter life tends to be long.

Flumes are available in a wide range of types (long and short throated), styles (Parshall, Palmer Bowlus, Ramp, etc.) and sizes. It would be a rare application where a suitable flume could not be used (naturally assuming the application is a sub-critical, open channel flow one to begin with).

Disadvantage

Ultrasonic flow meters may be affected by wind, steam, and air temperature gradients. Additionally, turbulence, foam, and floating debris may provide artificially high flow reading as the meter may detect these before it detects the true surface level of the flow stream.

Because the speed of sound changes with air temperature, an ultrasonic flow meter should compensate for changes in air temperature. Additionally, sunlight can impact sensor performance by artificially heating the sensor.

Flumes are designed to be level from front-to-back and from side-to-side. Although corrections have been developed for Cutthroat and Parshall flumes, corrections are not available for other flumes.

Downstream, backwater effects can limit the actual discharge through a flume. Some flumes (Palmer Bowlus, Trapezoidal, and RBC) have a high resistance to the effects of submergence. Other flumes (H Type and Montana) have little to no resistance. When designing a flume installation, free flow conditions are always desired.

Accurate measuring open channel flows is difficult. Overall systems accuracies better than 8-10% should not be expected and are not practical. For a system requiring greater accuracy, a closed-pipe solution would be required.

Although flumes are static devices and ultrasonic meters mount out of the flow stream, maintenance is still required. Flumes must be kept clear of sediments and debris as well as periodically inspected for proper site and flow conditions. Ultrasonic meters may require that condensation and debris be cleaned off the sensor face. Additionally, ultrasonic sensors drift over time. Regardless of the meter or manufacturer, periodic calibration will be required.

Images: Pulsar, Ultrasonic Flow Meter Information: ISCO Open Channel Flow Meaurement Handbook, Sixth Edition

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID