When we wrote our article on Ways to Screw Up a Flume Installation, we touched on some of the basic ways that an installation can go awry. Many of the possibilities mentioned came from the installation conditions.

Here we delve into more of the application errors and deliberate actions we see.

Undersizing Flume

It sounds basic that the flume should be able to handle the maximum flows that a site is expected to see. Sometimes we don’t have all the data to make an informed decision. In that event, we have to do our best. That said, it is generally better to oversize a flume than it is to undersize a flume.

Using the Wrong Flume Material

Not all flume materials are equal. We know that many of you need to make sure each penny is accounted for and certainly we try to be material neutral, but there are times when certain materials just don’t work for certain applications.

For example: Galvanized steel is perfectly fine for water rights / irrigation applications. The application isn’t particular challenging, the flow streams are benign, and there aren’t unusual environmental stresses. Galvanized steel should not, however, be used when there is an element of sanitary solids in the flow stream or where corrosive chemicals. For those applications, fiberglass (sanitary solids) and stainless steel (corrosive chemicals) are better choices.

Taking the Stiffening Angles Off the Flume

The stiffening angles at the top of a flume are there for a very particular reason: to ensure dimensional accuracy. The angles should be LEFT ON THE FLUME at least until the installation has been completed.

More than once a contractor who skipped cribbing a flume had to pull it out and put a new one in. While we like to make a sale, we never want to make repeat sales because of this. Take your time and do it right.

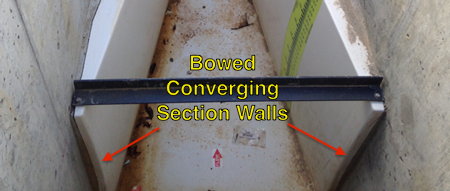

Undersizing the Connecting Pipe

In Ways to Screw Up a Flume Installation, we mentioned that the flow coming into the flume must be under open channel (non-full pipe) conditions at all times. An extension of this is makign sure that the connecting pipe can adequately handle the flow rate. Again, you would think this is a no-brainer, but look at the photo below from a food processing plant. Apaprently obvious isn't alway obvious.

On the inlet, an undersized pipe will mean that the flow comes into the flume under pressurized condtions. On the outlet, an undersized pipe means that flow cannot get out of the flume quick enough with the result that flow backs up into the flume and eventually over the sidewalls.

As exhaustive as our flume installation instructions are, it doesn’t hurt to remind you of them every once and again!

Image: MADCS, 2010 Montana Association of Dam and Canal Systems Workshop