This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

Case Study - Solutia - Industrial Flow Measurement

Case Study

Case Study

Monitoring industrial flows in lined concrete channels

Customer

Solutia, Inc., a subsidiary of Eastman Chemical Company

Background

Built in 1953, the Pensacola Plant is situated on a 2200 acre tract, 12 miles north of the City of Pensacola, on the Escambia River. Solutia is the world's largest producer of nylon carpet staple. The facility produces nylon polymer chips for the automotive and electrical industries. Some of the adipic acid produced is sold outside the fiber market where it goes into food additives -- Jell-O® and NoSalt® to provide tartness. The facility also produces maleic anhydride, which utilizes butane as a raw material.

Problem

Solutia needed to measure interplant flows in several existing concrete channels. The concrete channels had a protective coating for resistance to adipic acid and could not be modified. Any flow solution would have to be drop in place and secured with specialty mastic. Also, each channel was different in cross-section, but a standard flow solution was desired.

Solution

The relatively flat topography of the Panama City area meant that the existing channels had little in the way of slope to them. As the channels already existed and could not be modified, devices requiring high head loss (weirs) or free-spilling discharges (H type and Montana flumes) could not be used. Additionally, one channel had a relatively shallow depth; which served to determine the maximum upstream head that any solution could generate.

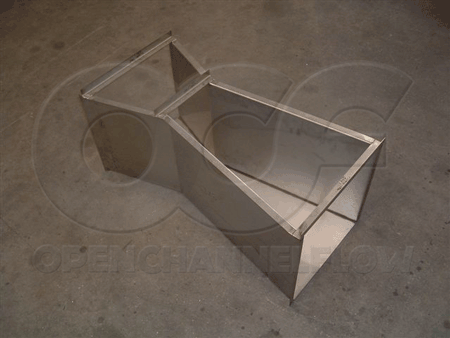

The relatively flat channels and maximum upstream head considerations made the down select to either a Trapezoidal or Cutthroat flume. Of these, the Cutthroat flume offered the greatest adaptability to the existing conditions. The rectangular shape of the channel matched well with the Cutthroat’s cross-section the flow ranges of the Cutthroat matched up well with the flows in the various channels.

After considering both fiberglass and stainless steel construction, Solutia settled on mill finished T-304 stainless steel. The material was compatible with the flow stream chemicals and, almost as important, could be fabricated in such a way that the flume floor added little in the way of height to the water level (1/8-inch [0.3175 cm] vs. 1/4-inch [0.635 cm] for fiberglass construction).

Flumes for all three channels were approved and fabricated with installation occurring during a previously planned weekend plant shutdown.

Source: Wikimapia

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID