This website uses a variety of cookies, which you consent to if you continue to use this site. You can read our Privacy Policy for

details about how these cookies are used, and to grant or withdraw your consent for certain types of cookies.

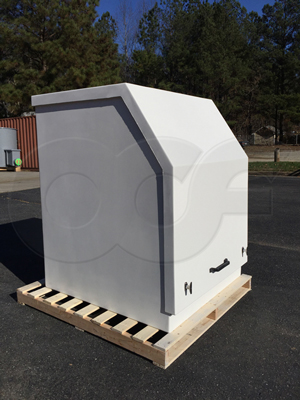

Fiberglass Enclosures for Automatic Samplers

While many automatic wastewater samplers on the market today tout NEMA 4X housings, the need to house and protect them has not gone away.

Whether the need is to protect the sampler from vandalism or the corrosive effects of a treatment plant environment, Fiberglass Sampler Enclosures from Openchannelflow are there to protect your investment.

Sampler Enclosure History

Years ago when the ISCO’s 3700 series samplers were the mainstay of treatment plants, samplers were relatively compact units. But as the years went by and samplers began to add bulk, the enclosures designed to house them (200-041) were simply too small.

Attempts were made to increase enclosure size (200-091 for the ISCO 6712FR), but with the advent of ISCO’s 4700 / 5800 (and Hach’s response the AS950 AWRS), even this larger enclosure was insufficient and a larger one was needed (200-095).

Our Approach

When we sat down to design our Gemini Sampler / Equipment Enclosure we considered years of customer feedback from the Tracom 200-091 / 200-095 enclosures we had designed years before.

In particular we were concerned about how the customer can best access the important components of the sampler. We also looked at trends in the overall composite sampler market.

The primary areas of concern were:

- Positive door sealing

- Maximum operator access

- Stability in high winds

- Operator safety

- Versatility

Positive door sealing was a concern as experience had shown that two door (top / front) designs were prone to leaking under the right conditions. This may not a problem when an already NEMA 4X sampler is inside the enclosure, but some times the enclosures were used to house other equipment that was NEMA rugged.

After looking at several different design approaches, we settled on a gull-wing door for the enclosure. The gullwing design opened up the whole of the interior to the operator. Also, as we had size Gemini Enclosure for future sampler grown, the door was sufficiently large to act as weatherhood – allowing the operator to be protected from the elements while they went about their work.

With such a large door naturally our thoughts went to wind stability and operator safety. To that end, the decision was made to use oversized dual redundant gas struts to support the door. This decision securely anchors the gullwing door to the enclosure body but also means that the door cannot inadvertently close – as we found out can happen with the star-wheel arm used on the Tracom 200-091 / 200-095 sampler enclosures. The approach is unique in the market place, with the closest enclosure being the Plasti-Fab Models 4A / 4B with their wound springs.

Specifically designed with flat sides, the Gemini Enclosure can mount other equipment (usually open channel flow meters) can be mounted inside of or outside on the enclosure – something not possible with competing sampler enclosures with ribbed exteriors or angled doors.

Like our line of walk-in fiberglass equipment shelters, Openchannelflow Gemini Sampler / Equipment Enclosures are thoroughly insulated with R~14 walls and an R~7 door. Additionally, HVAC accessories can include thermostatically controlled exhaust fans, passive ventilators, and stainless steel utility heaters (hard wired to avoid the potential of tip over).

In addition to our regular sampler enclosures, Openchannelflow also offers custom sampler enclosures to fit our clients’ specific site needs, while smaller portable samplers can be house in our low profile Redstone Enclosures.

Related Blog Posts

Explore more insights in our blog.

LOCATIONS IN ATLANTA, GA & BOISE, ID