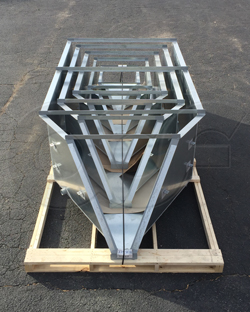

Galvanized Steel H Flumes are an economical alternative to standard fiberglass construction. Galvanized Steel H Flumes are commonly used to measure irrigation, surface water, and runoff flows.

Galvanized Steel H Flumes are an economical alternative to standard fiberglass construction. Galvanized Steel H Flumes are commonly used to measure irrigation, surface water, and runoff flows.

Galvanized Steel Advantages

Galvanized steel H Flumes from Openchannelflow are economical, have good damage resistance, and are available with accessories and mounting / end configuration options.

Damage Resistance

The heavy gauge construction of Openchannelflow galvanized steel H Flumes provide good damage resistance. In irrigation / water rights applications this can be useful, particularly when cattle or other livestock may be in / around the flume.

Economical

Galvanized steel H Flumes are economical - generally being the least expensive H Flume material. The cost difference between galvanized steel and fiberglass H Flumes is not as great, though, as with Parshall flumes.

Configuration Flexibility

Openchannelflow galvanized steel H Flumes are available with a selection of accessories and mounting / end configuration options.

Contact Openchannelflow for additional details.

Galvanized Steel Disadvantages

While galvanized steel H Flumes have a number of advantages, it is important to remember that there are several disadvantages to the material.

Weight

Galvanized steel H Flumes weigh more twice as much as their fiberglass counterparts - on average ~5 lbs/ft2 [24.4 kg/m2]. This increased weight means that more manpower / heavier duty equipment is typically needed to install the flume. Additionally, the added weight means that galvanized steel H Flumes are not generally used in remote watershed applications unless damage resistance is needed.

Abrasion Resistance

The surface galvanization on the flumes can be abraded by heavy / sharp sediments in the flow stream. In applications where these are present their will be a need for ongoing maintenance of the galvanization or a different flume material (typically stainless steel) should be used.

Maintenance

Depending upon the application, the galvanized surfaces of the flume may present an ongoing maintenance issue. Where the hot dipped galvanization has been worn away, the surface must be dried, cleaned, and the cold galvanization applied.